أرسل لنا رسالة

line equipment for cement raw material additives

Full article: An overview of alternative raw materials used in cement

The composition of raw materials, additives, and fuel has a significant bearing on cement’s properties. Limestone used for cement production by different cement plants varies considerably in mineralogy, chemical composition, physical features, and microstructure.

Full article: Additive manufacturing of concrete in

1. The potential of additive manufacturing of concrete (AMoC) Concrete is the most used building material worldwide. Raw materials to produce

Sustainable iron-rich cements: Raw material sources and

202271 The main uses of Fe-rich raw materials in cements can be divided into three types: Fe-rich cement clinkers, Fe-rich supplementary cementitious materials, and Fe

(PDF) Sustainable iron-rich cements: Raw material Cement Raw Materials used in Manufacturing of Cement :Raw MaterialsCementite In Iron-Carbon Diagram

Prodexim International inc. Additives for cement and concrete

PDX-105 additives should be used at dosages of 0.02 to 0.05% by weight of cement (between 200 and 500 ml per ton). The optimal dosage should be determined during

:Concrete And CementConcrete Additives

Construction Chemicals, Concrete Admixtures

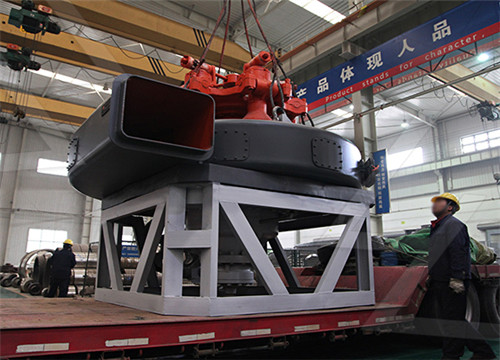

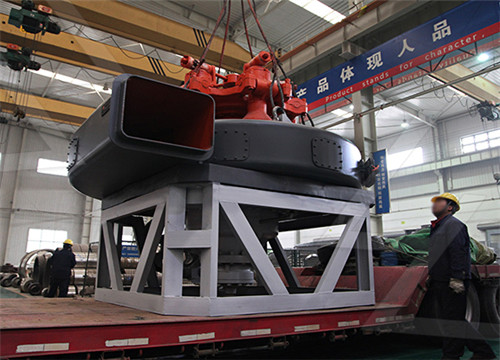

2023526 Equipment: 1. Production line designing technical requirements and physical on-site conditions. Conducting preliminary feasibility analyses. 2. Providing essential equipment specifications,

Ultra-high performance concrete: Mix design, raw materials

202361 The main raw materials for preparing UHPC are: aggregate (coarse aggregate and fine aggregate), cementitious material (cement and mineral admixture),

:Concrete And CementRaw MaterialsCivil EngineeringWet Packing Theory

Review on vertical roller mill in cement industryits

202111 There are three types of cement manufacturing processes wet, semi-dry and dry processes. In the wet/semi-dry process, the raw materials are produced by

:Concrete And CementRaw MaterialsPublish Year:2021Limestone

Additive Manufacturing with Cement-based Materials NIST

2017121 Additive Manufacturing (AM) with concrete, also known as 3-D Concrete Printing (3DCP), is an emerging technology in the construction industry. This approach to

:Concrete And CementAdditive Manufacturing3D Printing Concrete Additives

Extrusion-Based Additive Manufacturing of

201974 The aim of this review was to show in detail a general panoramic of extrusion-based additive processes in the construction sector; the main advantages of using additive manufacturing with the respect to

:Additive ManufacturingBinder JettingMarco Valente, Abbas Sibai, Matteo Sambucci

Sustainable cement production—present and future

201171 By definition, concrete crusher sand has a grading of 0 to 2 mm and is obtained when recycled aggregates are generated from crushed concrete. Its use as a

:Concrete And CementCement Industry FutureCement Production In India 2022

Cement Extraction, Processing, Manufacturing Britannica

Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be

Stacker and reclaimer systems for cement plants

20181220 buffer storage of raw materials, stacker and reclaimer systems have an impressive track record of performance. has commissioned some of the largest stackers and reclaimers in the cement industry, matching kiln through-puts of up to 12,000-13,000 tpd. We offer an extensive selection of stacker and reclaimer systems to

Supply Chain Management in the Cement Industry

2016813 Cement is produced in more than 150 countries all over the world. Cement, as the most important ingredient of concrete, is essential in the development of infrastructure and construction in general. The level of advancement in cement and concrete Supply Chain Management (SCM) can facilitate or constrain world economic development.

Evaluation of chemical, mineralogical and clinker burnability

2019121 The addition of Fe2O3 (Iron Ore) and Al2O3 (bauxite) to the raw material is expected to act on the baking facilitator The LSF values were determined to be 98 when raw material compositions were formed and cement modules were calculated according to the Bogue formula using the raw meal chemical analysis (Table 3). The LSF value expected

Extrusion-Based Additive Manufacturing of Concrete

201974 Additive manufacturing is one of the main topics of the fourth industrial revolution; defined as Industry 4.0. This technology offers several advantages related to the construction and architectural sectors; such as economic; environmental; social; and engineering benefits. The usage of concrete in additive technologies allows the

AVAILABLE AND EMERGING TECHNOLOGIES FOR

2021625 Testing and Materials (ASTM) Specification C-150. Cement is produced from raw materials such as limestone, chalk, shale, clay, and sand. These raw materials are quarried, crushed, finely ground, and blended to the correct chemical composition. Small quantities of iron ore, alumina, and other minerals may be added to adjust

Cement Crusher Crusher In Cement Plant AGICO Cement

Raw materials of the cement plant are mostly from open-pit mines, and the ore usually has a large particle size. In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process

CEMENT RAW MATERIALS International Cement Review

201369 The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone. Clayey raw material accounts for between 10–15%, although the precise amounts will vary. Magnesium carbonate, which may be present in limestone, is the main undesirable impurity. The level

Extrusion-Based Additive Manufacturing of Concrete

201974 Additive manufacturing is one of the main topics of the fourth industrial revolution; defined as Industry 4.0. This technology offers several advantages related to the construction and architectural sectors; such as economic; environmental; social; and engineering benefits. The usage of concrete in additive technologies allows the

Adhesives production, raw materials, classification

2018829 The PCC Group’s offer for the adhesive industry. The PCC Group is a producer of a wide range of polyether polyols ( Rokopol® series) that can be used for the production of prepolymers, often referred to as one-component adhesives. They are a part of the polyol component in polyurethane two-component adhesives and can also be found

(PDF) Effects and Control of Chemical

20201015 A new development has produced a continuous on-line mineral analyser using XRD to analyse the various mineral phases present in dry materials (clinker, cement or raw materials) in virtually real

Cement-Based Repair Materials and the Interface

202246 Surface damages usually occur in concrete structures. In order to restore the functions and prolong the service life of concrete structures, their surface damages should be repaired in time. This stone

Zunivugedamamebogugeduku PDF Cement Mill

2021528 Our cement crusher can completely crush the raw material, reduce the size of feed to the mill and increase the reaction of the raw material in the cement production process below, reducing the energy consumption of the entire cement production line. Cement factory Cement factory is another necessary cement equipment of cement

Analysis of material flow and consumption in cement production

2016120 1. Introduction. Over the last century, Portland cement-based concrete has become the highest manufactured product on Earth in terms of volume. Concrete is used worldwide as a building material and is the most consumed substance on Earth after water (Sakai, 2009).The volume of concrete produced globally is approximately 5.30 billion m 3

Sustainable cement production—present and future

201171 At the same time, the cement industry is facing challenges such as cost increases in energy supply, requirements to reduce CO 2 emissions, and the supply of raw materials in sufficient qualities and amounts. The World Business Council for Sustainable Development and its Cement Sustainability Initiative, comprising cement producers

Cement Production Process AGICO

2020825 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storage.

Clinker Production an overview ScienceDirect Topics

Assessing the environmental impact of conventional and ‘green’ cement production. G. Habert, in Eco-efficient Construction and Building Materials, 2014 Energy efficiency. Energy demand in clinker production has been significantly reduced over the last few decades. The theoretical minimum primary energy consumption (heat) for the chemical and

Ultra-high performance concrete: Mix design, raw materials

202361 Ultra-high performance concrete (UHPC) is a cutting-edge material that offers superior properties and applications in civil engineering. This review article provides a comprehensive overview of the mix design, raw materials and curing regimes of UHPC, as well as the latest research and development trends in this field.

Cement Production an overview ScienceDirect Topics

Assessing the environmental impact of conventional and ‘green’ cement production. G. Habert, in Eco-efficient Construction and Building Materials, 2014 10.1 Introduction. Cement production has undergone tremendous developments since its beginnings some 2,000 years ago. While the use of cement in concrete has a very long history (Malinowsky, 1991), the

Volume 3, Issue 5, November 2013 Study of Processing

2014114 A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement. Dry raw mills additives and transfer it to raw mill. This raw mill consists of 3 Cement raw materials are mainly quarried, and so contain a certain amount of natural moisture. Attempting to grind a wet material is unsuccessful

Prodexim International inc. Additives for cement and concrete

PDX-105 additives should be used at dosages of 0.02 to 0.05% by weight of cement (between 200 and 500 ml per ton). The optimal dosage should be determined during

Construction Chemicals, Concrete Admixtures

2023526 Equipment: 1. Production line designing technical requirements and physical on-site conditions. Conducting preliminary feasibility analyses. 2. Providing essential equipment specifications,

Ultra-high performance concrete: Mix design, raw materials

202361 The main raw materials for preparing UHPC are: aggregate (coarse aggregate and fine aggregate), cementitious material (cement and mineral admixture),

Review on vertical roller mill in cement industryits

202111 There are three types of cement manufacturing processes wet, semi-dry and dry processes. In the wet/semi-dry process, the raw materials are produced by

Additive Manufacturing with Cement-based Materials NIST

2017121 Additive Manufacturing (AM) with concrete, also known as 3-D Concrete Printing (3DCP), is an emerging technology in the construction industry. This approach to

Extrusion-Based Additive Manufacturing of

201974 The aim of this review was to show in detail a general panoramic of extrusion-based additive processes in the construction sector; the main advantages of using additive manufacturing with the respect to

Sustainable cement production—present and future

201171 By definition, concrete crusher sand has a grading of 0 to 2 mm and is obtained when recycled aggregates are generated from crushed concrete. Its use as a

Cement Extraction, Processing, Manufacturing Britannica

Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be

Stacker and reclaimer systems for cement plants

20181220 buffer storage of raw materials, stacker and reclaimer systems have an impressive track record of performance. has commissioned some of the largest stackers and reclaimers in the cement industry, matching kiln through-puts of up to 12,000-13,000 tpd. We offer an extensive selection of stacker and reclaimer systems to

Supply Chain Management in the Cement Industry

2016813 Cement is produced in more than 150 countries all over the world. Cement, as the most important ingredient of concrete, is essential in the development of infrastructure and construction in general. The level of advancement in cement and concrete Supply Chain Management (SCM) can facilitate or constrain world economic development.

Evaluation of chemical, mineralogical and clinker burnability

2019121 The addition of Fe2O3 (Iron Ore) and Al2O3 (bauxite) to the raw material is expected to act on the baking facilitator The LSF values were determined to be 98 when raw material compositions were formed and cement modules were calculated according to the Bogue formula using the raw meal chemical analysis (Table 3). The LSF value expected

Extrusion-Based Additive Manufacturing of Concrete

201974 Additive manufacturing is one of the main topics of the fourth industrial revolution; defined as Industry 4.0. This technology offers several advantages related to the construction and architectural sectors; such as economic; environmental; social; and engineering benefits. The usage of concrete in additive technologies allows the

AVAILABLE AND EMERGING TECHNOLOGIES FOR

2021625 Testing and Materials (ASTM) Specification C-150. Cement is produced from raw materials such as limestone, chalk, shale, clay, and sand. These raw materials are quarried, crushed, finely ground, and blended to the correct chemical composition. Small quantities of iron ore, alumina, and other minerals may be added to adjust

Cement Crusher Crusher In Cement Plant AGICO Cement

Raw materials of the cement plant are mostly from open-pit mines, and the ore usually has a large particle size. In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process

CEMENT RAW MATERIALS International Cement Review

201369 The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone. Clayey raw material accounts for between 10–15%, although the precise amounts will vary. Magnesium carbonate, which may be present in limestone, is the main undesirable impurity. The level

Extrusion-Based Additive Manufacturing of Concrete

201974 Additive manufacturing is one of the main topics of the fourth industrial revolution; defined as Industry 4.0. This technology offers several advantages related to the construction and architectural sectors; such as economic; environmental; social; and engineering benefits. The usage of concrete in additive technologies allows the

Adhesives production, raw materials, classification

2018829 The PCC Group’s offer for the adhesive industry. The PCC Group is a producer of a wide range of polyether polyols ( Rokopol® series) that can be used for the production of prepolymers, often referred to as one-component adhesives. They are a part of the polyol component in polyurethane two-component adhesives and can also be found

(PDF) Effects and Control of Chemical

20201015 A new development has produced a continuous on-line mineral analyser using XRD to analyse the various mineral phases present in dry materials (clinker, cement or raw materials) in virtually real

Cement-Based Repair Materials and the Interface

202246 Surface damages usually occur in concrete structures. In order to restore the functions and prolong the service life of concrete structures, their surface damages should be repaired in time. This stone

Zunivugedamamebogugeduku PDF Cement Mill

2021528 Our cement crusher can completely crush the raw material, reduce the size of feed to the mill and increase the reaction of the raw material in the cement production process below, reducing the energy consumption of the entire cement production line. Cement factory Cement factory is another necessary cement equipment of cement

Analysis of material flow and consumption in cement production

2016120 1. Introduction. Over the last century, Portland cement-based concrete has become the highest manufactured product on Earth in terms of volume. Concrete is used worldwide as a building material and is the most consumed substance on Earth after water (Sakai, 2009).The volume of concrete produced globally is approximately 5.30 billion m 3

Sustainable cement production—present and future

201171 At the same time, the cement industry is facing challenges such as cost increases in energy supply, requirements to reduce CO 2 emissions, and the supply of raw materials in sufficient qualities and amounts. The World Business Council for Sustainable Development and its Cement Sustainability Initiative, comprising cement producers

Cement Production Process AGICO

2020825 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storage.

Clinker Production an overview ScienceDirect Topics

Assessing the environmental impact of conventional and ‘green’ cement production. G. Habert, in Eco-efficient Construction and Building Materials, 2014 Energy efficiency. Energy demand in clinker production has been significantly reduced over the last few decades. The theoretical minimum primary energy consumption (heat) for the chemical and

Ultra-high performance concrete: Mix design, raw materials

202361 Ultra-high performance concrete (UHPC) is a cutting-edge material that offers superior properties and applications in civil engineering. This review article provides a comprehensive overview of the mix design, raw materials and curing regimes of UHPC, as well as the latest research and development trends in this field.

Cement Production an overview ScienceDirect Topics

Assessing the environmental impact of conventional and ‘green’ cement production. G. Habert, in Eco-efficient Construction and Building Materials, 2014 10.1 Introduction. Cement production has undergone tremendous developments since its beginnings some 2,000 years ago. While the use of cement in concrete has a very long history (Malinowsky, 1991), the

Volume 3, Issue 5, November 2013 Study of Processing

2014114 A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement. Dry raw mills additives and transfer it to raw mill. This raw mill consists of 3 Cement raw materials are mainly quarried, and so contain a certain amount of natural moisture. Attempting to grind a wet material is unsuccessful