أرسل لنا رسالة

conveyor used in cone crusher

Size reduction control in cone crushers ScienceDirect

2021111 The flowsheet consists of a 10 m 3 intermediate feed bin, a vibrating bin feeder, a Metso GP500 Hydrocone-type cone crusher (medium crushing chamber), two Kivisampo A132 screens, and 7 belt conveyors. The GP500 crusher is equipped with

A review of modeling and control strategies for cone crushers

2021815 Note that a complete crushing circuit consists of more than the cone crusher alone. Conveyor belts for material transport, silos and bins for intermediate

Cone Crusher an overview ScienceDirect Topics

Cone Crusher. Cone crushers give the best results when operating in closed circuit with screens. From: The Science and Technology of Cement and Other Hydraulic Binders,

Gyratory and Cone Crusher ScienceDirect

201611 The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required.

REAL-TIME OPTIMIZATION OF CONE CRUSHERS CORE

20171122 Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely

DEM-based design of feed chute to improve performance of cone crushers

202171 In the tertiary cone crusher circuit, the feed after exiting from a bin through a conveyor belt (with speed of 16 m/min) enters a structure (main body) supporting a cubic

Cone Crushers Moore Watson Ltd

The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plants. The hydraulic

MCO 90i EVO2 Mobile cone crushers mpl Wirtgen

Cone crusher with large stroke for maximum crushing capacity; 3-arm crusher design for high throughput; High crusher drive power for a continuous crushing process and higher

Crusher an overview ScienceDirect Topics

The common secondary crushers are cone, roll, and impact types. The cone crusher ( Fig. 13.12) is very similar to the gyratory type, except that it has a much shorter spindle with a

Types of Crushers: What You Need to Know Machinery

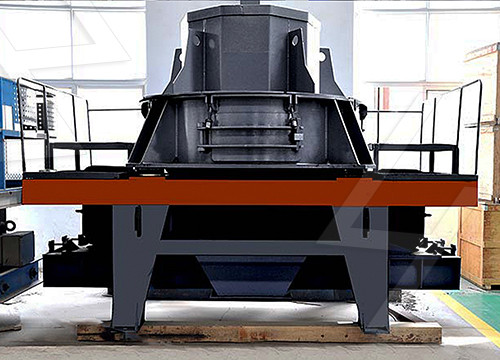

Cone crushers. Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Metso MP Series Technical Reference

Do not open the hatch when the rotor is moving. Lock the rotor before entering the crusher. 0-45 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL Page 54 SECTION 0 SAFETY Watch out for

Cone Crushers Moore Watson Ltd

Cone crusher Cone crushers CC100 CC200 CC400 CC300 MHP400 MHP500. Cone crusher Cone crushers CC100 CC200 CC400 CC300 MHP400 MHP500 / top of page. its performance is in part dependent

Cone Crusher an overview ScienceDirect Topics

Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediate-range size-reducing machines. A schematic diagram of a cone crusher is shown in Fig. 4.6 A.The drive is similar to that of a gyratory crusher. The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the

REAL-TIME OPTIMIZATION OF CONE CRUSHERS CORE

20171122 Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation and, to some extent, increasing production. These systems ordinarily focus on the crusher and not the yield of production process.

What are the different types of cone crushers? LinkedIn

2023228 mpl mineral. There are three main types of cone crushers: the Standard Cone, the Short Head Cone, and the Hydrocone. The Standard Cone crusher typically has a medium-sized feed opening

Patriot® Cone Crusher Secondary or Tertiary Crusher

20231027 High Performance Bushing Cone. Superior’s Patriot Cone Crusher is an American-made, bushing-style rock crusher that sets the standard for productivity and durability. With a lifetime warranty and high-grade components that exceed industry standards, the Patriot Cone delivers reliable performance and unbeatable value in

Gyratory and Cone Crusher ScienceDirect

201611 A conveyor belt fed a Run-of-Mine iron ore to a gyratory crusher, which had a gape of 356 cm. The maximum opening at the discharge end was 15.0 cm and the close set 4.5 cm. Eighty percent of the feed and product was less than 15.0 and 2.4 cm, respectively. A cone crusher of height 2.1 m, open side feed opening 30.4 cm and a

CONE CRUSHING INDUSTRIES ENHANCE

2022715 C (149 °F). A cone crusher immediately stop if the oil return line temperature exceeds 68 °C (154 °F). N.Oil level : In our system oil level manually check and fill as per require. In advance control system oil level sensor signal provide to controller input and monitor in display unit. O.Puppet valve : This valve use at below the cone

Crushed concrete: The pros, cons and FAQs Machinery

65' Tracked Radial Stacker Conveyor. Conveyors. Conveyors. TR100-48. Barford. 100' Tracked Stacker Conveyor. and pass it through a crusher or shredder to turn it into crushed concrete. the concrete crack, weaken it, and look bad. It can also cause the concrete to expand, resulting in "popouts" where cone-shaped pieces break off from the

Cone mine crusher dust collector design meets emission

201946 Cone mine crusher dust collector design meets emission standards. 04-06-2019. The cone crusher is a professional equipment for crushing medium and above materials. Generally, there are four kinds of crushing chambers such as coarse, medium, fine and superfine. In addition to sand, it can also be widely used in metal mines, cement

® GP220™ cone crusher Metso

® GP220™ cone crusher is one of the smaller models in ® GP Series™ cone crushers family. It is traditionally used as secondary, tertiary, or quaternary crusher especially in aggregates

Portable Cone Plants Astec

20231029 A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. Our portable cone crushing plants meet coarse and fine crushing application requirements and offer on-the-fly adjustability for easy operation. 7:41.

Crushers All crusher types for your reduction needs Metso

However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher. Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage. Cone crushers can in most cases also give a good cubic shape to fine grades.

P&Q University Lesson 7: CrushingSecondary Breaking

201992 Whether it’s a solo cone crusher, one used in addition to a triple-deck screen for closed-loop operation, or various-size cone crushers with a double-deck screen and oversize return conveyor, a suitable plant will be available for almost every task. Mobile cone crushers may be available with or without integrated screen units.

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

Coal Crushing and Conveyer System Research Publish

Various types of crusher available for crushing like jaw crusher, gyratory crusher, cone crusher, Impact crusher, Double roll crusher, pulverizers, ring granulators etc. The crushed coal is transported from crusher to thermal power plant through conveyor belt and is used in boiler. The type of conveyors used for transferring the coal are listed