أرسل لنا رسالة

cleaning extrusion dies by sand

Maintenance Tips: Cleaning Your Extrusion Die

4 06, 2023 At least once a year, a flat extrusion die for film, sheet, or coating must be disassembled for standard maintenance--a procedure called a "split and clean." Typically, a falloff in production quality indicates that a split and clean is required.

Special report: High-tech alternatives for extrusion die

Cleaning of Extrusion dies how? Extrusion Training

Extrusion Die Cleaning: Effective Techniques for Mold and Die Cleaning

20231026 Conventionally, the cleaning of extrusion dies, press tools, molds, and other production equipment is a labor-intensive and time-consuming process that often

Thermal Cleaning SCHWING Technologies North

Depending on the type of the polymer and size or geometry of the extrusion components, cleaning can be performed without requiring disassembly. Cleaning systems remove all polymer and eliminate risk of thermal or

Extrusion Dies for Plastics and Rubber Design and

This definitive book provides a comprehensive account of the full range of dies used for extrusion of and elastomers. The distinctive features of the various types of dies

Die Cleaning (Extrusion Die Cleaning) Kemet

20231030 Blog Articles for Ultrasonic Cleaning Die Cleaning (Extrusion Die Cleaning) Die Cleaning (Extrusion Die Cleaning) An ultrasonic cleaning machine cleans

Thermal Cleaning Accurate Thermal Systems

20231030 Fluidized Baths offer a fast, safe and efficient way to clean extrusion and injection molding parts some of which are listed below. Important: Fluidized Baths are not grit or media blasters, they thermally

Dynisco PolyClean Fluidized Temperature Bath

2018413 Dynisco PolyClean Fluidized Bath. Dynisco’s PolyClean is a fluidized temperature bath that will clean parts and tooling 2 to 3 times faster and safer than

System Allows Fast, Efficient Die Cleaning Plastics Technology

2021722 The system was designed with the goals of flexibility, ease, and operator safety in regards to maintenance and upkeep of an extrusion die. PTi says the uCAMS is

Mastering Aluminum Extrusion Die Polishing: Tips,

2023425 These dies are more intricate and challenging to design and manufacture compared to solid and semi-hollow dies. Hollow dies typically utilize a mandrel (or bridge) that supports the internal shape of the profile, ensuring the proper formation of the enclosed cavity during the extrusion process. The importance of die polishing in aluminum extrusion

Burn Off Oven Thermal cleaning systems

Burn off ovens are designed for removing paint, powder coating, epoxies, lacquers, urethanes and other organic or inorganic compounds from a variety of parts, such as: racks, hooks, jigs, fixture. And also for cleaning

What is Aluminum Extrusion? The Process in 10

1 Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile. Aluminum extrusion can be likened to squeezing toothpaste from a tube. A powerful

Cleaning of extrusion dies E I Du Pont de Nemours and

20121030 Cleaning of extrusion dies . United States Patent . Abstract: Extrusion dies may be cleaned, especially of so-called die drips, by passing a wire over the die orifices in the vicinity of the exit face of the extrusion die. The operation of the extrusion operation is not affected by the passing of the wire through the stream(s) of the

Modelling and Technology Development M-TD

202032 The cleaning of extrusion dies is essential for their maintenance. However, it generates a a large quantity of environmentally unfriendly waste. MTD offers to extract the residual aluminium by placing the extrusion die into a solution of caustic soda with a concentration of 25 35%, in accordance with the latest EHS requirements. After the

WOA1 Process for recovering caustic soda solutions from

In order to remove aluminum from the reflux liquors from the pickling process of extrusion dies and to regenerate the NaOH solution for re-employing the same in subsequent pickling processes, the process of synthesizing of zeolites is exploited, by previously adding a suitable source of silicon, said process of synthesis allowing the sodium hydroxide

The best alternative tools to sandblasting MontiPower

2017719 The alternative to sandblasting: Bristle Blaster® and MBX®. With the power tools from MontiPower, sandblasting is a thing of the past. No sand and no blasting tools; With the Bristle Blaster® and MBX® you can quickly and easily clean surfaces from corrosion and other layers of dirt. Not just cleaning; the patented technology of the power

5.3.3 Finishing Operations Forging Industry Association

201685 Home. 5.3.3 Finishing Operations. There are two categories of finishing operations: those that produce minor dimensional corrections, and surface treatment processes. Coining, sizing and straightening are commonly used to improve the dimensional accuracy of forgings. When tolerances closer than those that can be economically

Project noufflard.fr

Dec 3 2013 Worker drowned in pond while cleaning it Fatality 9 16 Plant manager died after being engulfed in sand bin extrusion press Fatality side shear and streamlined extrusion dies for 3D flow analysis inside shear and streamlined extrusion dies for feeder plate The capabilities of DEFORMTM 3D had been evaluated and vali

Vacuum Oven For Cleaning of Extrusion Die Thermal cleaning systems

Vacuum pyrolysis oven is one of SNT’s most popular thermal cleaning systems. Vacuum pyrolysis cleaning oven is designed specially for cleaning polymers from a variety of metal parts and it can clean almost all of polymers (PP, PE, PET, PA, TPE, PB, PVC, PC, PMMA, ABS, etc.). CE approved. Category: Vacuum Pyrolysis Cleaning Oven Tags: Removal

Extrusion tip and die manufacturer Esteves Group

The extrusion die controls the shape and size of the insulating material around the wire. State-of-the-art technology and tight concentricity (.0002”/0.005 mm) of Esteves Group extrusion tools give the insulator

Special Report: High-tech Alternatives for

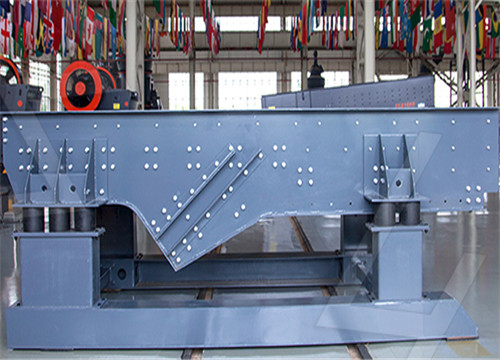

Regular cleaning of plastic extrusion dies and inspection for damage is necessary to ensure the quality of products, reduce scrap and extend the life of the die. Dinamec Systems provides fluidized silica sand-bed

Maintenance Tips: Cleaning Your Extrusion Die nordson

202346 Using an assortment of brass scrapers, remove all of the polymer from the flow surface, the front lip edge, and the seal surface. Scrape the die lengthwise where possible. Next apply the die soap to all of the above surfaces, working on one section (about two feet) at a time. The soap will melt as it is applied.

Die Cleaning Compact Tecalux

Tecalux Compact die cleaning system is the reliable, plug and play, affordable solution able to manage the high temperature extrusion die cleaning process in safety and convenient way. The system includes our treatment tanks model Tx in compact configuration able to work with liquid or flakes caustic soda Fitted on a preassembled steel frame with two die

Applied Sciences Free Full-Text Effects of Solid Die Types

20191229 Aluminum extrusion dies can be divided into three basic types: solid die, semi-hollow die, and hollow die, in which the solid and the semi-hollow dies are used for extruding solid profile products, and hollow die is used for fabricating hollow profile products [1,2].In the aluminum extrusion with the solid die, a hot billet is supplied into the container

Extrusion dies cleaned with Kerry ultrasonics Guyson

2017620 Surface finishing experts Guyson International have recently installed a special Kerry Ultrasonic UCR (ultrasonic clean and rinse) machine for cleaning extrusion dies used for PVC extrusion into Eurocell Profiles Ltd, the UK’s market-leading manufacturer and distributor of quality PVC-U profiles used in windows, doors, conservatories and

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"":{"items":[{"name":"sbm 0 coal mines of india.md","path":"sbm 0 coal mines of india.md","contentType":"file

Applied Sciences Free Full-Text Effects of Solid Die Types

20191229 Aluminum extrusion dies can be divided into three basic types: solid die, semi-hollow die, and hollow die, in which the solid and the semi-hollow dies are used for extruding solid profile products, and hollow die is used for fabricating hollow profile products [1,2].In the aluminum extrusion with the solid die, a hot billet is supplied into the container

Die Soap Plastic Machinery Sales

Cleaning Dies, extruder screws and barrels. Description. Specification. Die Soap 12 bars/case; Main Ingredient Tripoli and or Silica 0.1 mg / M3, 60-70% Quickly remove carbon and plastic residues without time consuming hand polishing. Die Soap comes in 2" square by 9.5" long bars and weight approx. 2.5 lbs each. Problems cleaning your dies