أرسل لنا رسالة

coal mining conveyor systems

Coal Conveyors Conveyor Belts for Coal Handling SKE

Coal Mining ConveyorCoal Washing Plant ConveyorPower Plant Coal Fuel ConveyorCoal Coking Plant ConveyorCoal Conveyor For Steel PlantPort Coalship Loading ConveyorCoal Conveyor Component

Underground Coal Mining ConveyorUnderground coal mines may contain gas (methane), and coal is a flammable substance. Therefore, the primary requirement for selecting coal conveyor is to ensure the safety of underground coal transportation. You can choose solid woven belt conveyor, and steel cord belOpen Pit Coal Mining ConveyorCompared with underground coal mines, surface coal mines have better transportation conditions, and flame retardant and antistatic requirements are no longer the main requirements. The physical and mechanical properties should be given priority to, while safety performance shoulskecon

Conveyor Belt System COAL HANDLING PLANTSDesign of a Material Handling Equipment: Belt Conveyor

Optimal scheduling method for belt conveyor system in coal mine

2020101 An optimal scheduling method for the belt conveyor system in coal mine considering the silo virtual energy storage capability is proposed in this . The

: Yunfei Mu, Taiang Yao, Hongjie Jia, Xiaodan Yu, Bo Zhao, Xu Zhang, Chouwei Ni, Lijia Du

Coal Industry Conveyor Coal Conveyor Products ASGCO

Coal Conveyor Belt Systems West River Conveyors

20231030 Underground Conveyor Systems. West River Conveyors understands the multiple challenges of underground mining operations. Dust, long runs, and confined

:Belt Conveyor In Coal MineBelt Conveyor For MiningCoal Conveyors

Study and Design of Belt Conveyor System in Coal Mines

201618 Study and Design of Belt Conveyor System in Coal Mines has been written as a part of work and also to foster the use as a handbook for general applications in

:CoalMainak Mukherjee

Belt Tear Detection for Coal Mining Conveyors MDPI

2022317 In this , we summarized the background and related knowledge of defect detection methods for conveyor belt surfaces in coal mining environments,

:Belt Conveyor In Coal MineBelt Conveyor For MiningConveyor Belts

Study on Optimization of Coal Truck Flow in Open

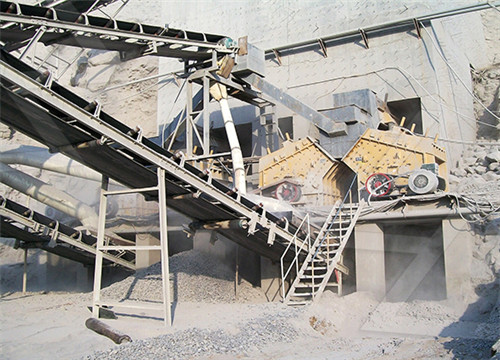

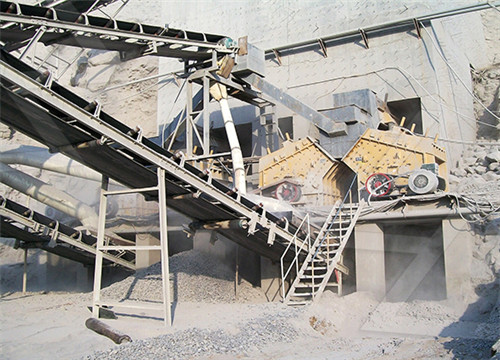

2020623 A semicontinuous process system consisting of a single-bucket excavator, truck, crushing station, and belt conveyor is the main coal mining process system of a large-scale hard coal open-pit mine. Through

:CoalPublish Year:2020Haiming Bao, Ruixin Zhang, Ruixin Zhang

Optimal operation of coal conveying systems assembled with crushers

2017715 Coal conveying systems are the critical auxiliary systems for coal dependent industries, like steelworks, cement plants, coking plants and coal-fired power

:CoalShirong Zhang, Wei MaoPublish Year:2017

Fresh Approaches for Coal Conveyors Coal Age

2020123 Conveyors serve as the arterial system for coal mines and prep plants. Longwalls and continuous miner sections are often limited by conveyor capacity and

A Faster and Lighter Detection Method for Foreign Objects in Coal Mine

2023710 Coal flow in belt conveyors is often mixed with foreign objects, such as anchor rods, angle irons, en bars, gangue, and large coal chunks, leading to belt tearing, blockages at transfer points, or even belt breakage. Fast and effective detection of these foreign objects is vital to ensure belt conveyors’ safe and smooth operation. This

Industrial Conveyor Belt System COAL

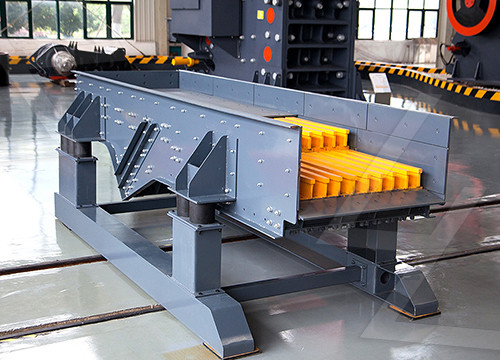

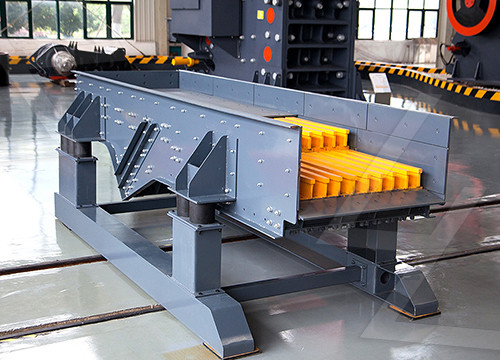

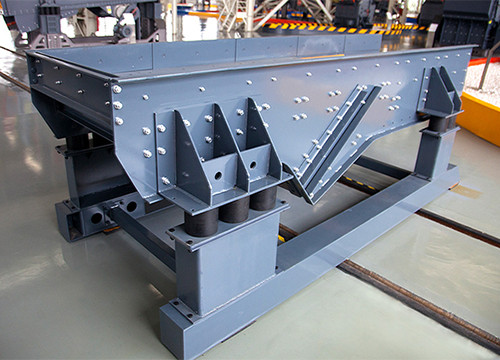

2 Industrial belt Conveyor Parts : 1. Conveyor Belt. The belt conveyor is an endless belt moving over two end pulleys at fixed positions and used for transporting material horizontally or at an inclined up. 2.

Optimal scheduling method for belt conveyor system in coal mine

2020101 How to optimize the operation of coal mine equipment for reducing energy consumption has become a hot issue to the coal mine enterprise. In recent years, the belt conveyor (BC) has become the most common equipment for coal transporting all over the world, and its energy consumption is second only to the mining system.

Advances in coal mining technology and sustainable mining

202311 The overall development of surface coal mining systems can be classified into two different stages. Before 1980, the shovel-train mining system was the major mining technology. During this period, around 10 of the 12 mines used shovel-train as the surface mining system, and only one used shovel truck and the other bucket wheel excavator

Coal Conveyor System SKE Industries

20231027 What is the applications of coal conveyor system? Coal conveyor is mainly used in conveying coal in mine, stockyard, port, in-land terminal, power plant, etc. Now we list some detail applications below: 1. Convey coal in open pit coal mining plant; 2. Transport coal in underground coal mining plant; 3. Stacking, reclaiming, and feeding

Comprehensive Conveyor Belt Systems for Mining CR Mining

Our conveyor belt cleaner systems remove up to 80% of carryback material. We supply a complete cleaning system including: Secondary belt cleaners, made from a variety of materials, including tungsten and polyurethane, to remove fine residual material. Conveyor belt ploughs to remove material on the return side of the conveyor belt, protecting

Belt Tear Detection for Coal Mining Conveyors PMC

2022317 The belt conveyor is the most commonly used conveying equipment in the coal mining industry. As the core part of the conveyor, the belt is vulnerable to various failures, such as scratches, cracks, wear and tear. Yan G. Research on visible light and infrared vision real-time detection system for conveyor belt longitudinal tear. IET Sci

Mining EU Solution INVT Solutions

Mining. According to customers' needs, INVT has provided various belt conveyor, hoist, winch, emulsion pump, mine fans, pumps and other products solutions for the coal mine industry. INVT Medium Voltage VFD Applied to Vent Fan in South Africa. In this case,through introducing INVT GD5000 medium voltage VFD applied to Vent fan in

Belt Tear Detection for Coal Mining Conveyors MDPI

2022317 The belt conveyor is the most commonly used conveying equipment in the coal mining industry. As the core part of the conveyor, the belt is vulnerable to various failures, such as scratches, cracks, wear and tear. Inspection and defect detection is essential for conveyor belts, both in academic research and industrial applications. In this

Transport systems Mining Technology

20211228 Belt conveyor in coal underground mine Drive station B=2250 mm, 4×1250 kW with PIOMA drive units Comprehensive solutions for underground transport system have a significant impact on the efficient production and high economic result of the mine. Transport systems by FAMUR Group fully satisfy and rationalize logistic needs of

Study on Optimization of Coal Truck Flow in Open

2020623 A semicontinuous process system consisting of a single-bucket excavator, truck, crushing station, and belt conveyor is the main coal mining process system of a large-scale hard coal open-pit mine. Through

Fresh Approaches for Coal Conveyors Coal Age

2020123 Longwalls and continuous miner sections are often limited by conveyor capacity and availability. Likewise, prep plants rely on conveyors to deliver raw coal and to transport clean coal and tailings to the refuse impoundment. Most of these operations run 24/7 and, if these systems go down, the mine begins to hemorrhage money.

Research on and Design of an Electric Drive

202369 Conveyor belts are widely used in ore transportation in large-scale mines for their long transportation range, high safety, and strong economic applicability. Coal mine belt conveyors are not only traditional,

A new paradigm for intelligent status detection of belt conveyors

2023531 Currently, it is developing in the direction of large-scale, intelligent[2], [3], and energy-saving[4], [5], [6]. Among them, the intelligence of belt conveyors is an important measure to actively respond to the call for energy conservation and emission reduction, reduce the labor intensity of workers, improve the reliability of system. Methodology

Research of Mine Conveyor Belt Deviation Detection System Based

2021123 The deviation detection system of belt conveyor based on machine vision is mainly composed of video acquisition, image processing and actuators. The video acquisition system mainly uses the mine camera as the image acquisition equipment, and transmits the video image to the industrial control computer of the dispatching room

Mining Free Full-Text Optimising Productivity and Safety of

202182 The open pit mining load and haul system has been a mainstay of the mining industry for many years. While machines have increased in size and scale and automation has become an important development, there have been few innovations to the actual load and haul process itself in recent times. This research highlights some of the

Conveyor systems Transportation Siemens Global Website

20231023 Moving mountains with mining conveyor systems. To meet worldwide demands for raw materials, underground and open-pit mines are being established in increasingly remote areas. Yearly billions of tons of bulk materials such as ore, coal, copper ore, and mining waste have to be moved powerfully, reliably, and efficiently. Mines

A new machine vision detection method for identifying and

2023314 Large foreign object transporting by coal mine conveyor belt may lead to production safety hazards. To reduce safety accidents during coal mining, a large foreign object detection method based on machine vision is proposed in this . An adaptive weighted multi-scale Retinex (MSR) image enhancement algorithm is proposed to

The Recent Technological Development of Intelligent Mining

201781 China’s coal mining technology is still advancing toward the level of the mining technology in Australia, Germany, and the United States. Software is the key of an intelligent mining system, as it allows all procedures along the work face to be controlled intelligently, including shearer cutting, pushing the scraper conveyor, moving

Mining Conveyors West River Conveyors

2 Conveyors for the mining industry vary from small and simple to large, complex systems. Since the mining of different products varies greatly, so do the requirements for conveyor systems, parts and even the services to maintain them. At West River Conveyors, we believe that customization is the key to getting the best conveyor system at the

خلط آلة طحن مع سعر 5hp

في ولاية تكساس كان

تشققت آلة محطم الصين

محطم شبه التلقائي الشحوم Systm الصانع

معدات ثقيله للبيع تاريخ2014 مستعمل

نمو سوق آلات البناء الصين

آلات التعدين عن الذهب

مرشح بديل لعنصر مرشح pall ultipleat سلسلة كاس

يستخدم أوم وكسارة الفك للبيع في الجزائر

الكرة مطحنة أجزاء النمر الآلات الصناعية كورب

مطور ومشغل منجم الزنك

produsen ponsel محطم

مشاريع مطحنة الكرة لالخبث في مصر

مطحنة الأسطوانة العمودية تزييت الإطارات

السلطة العرض نقطة على تأثير محطم

سعر كسارة الحجر التمساح

مطاحن السكك الحديدية للبيع

معدات تعدين الذهب التشغيل

ايستمان كسارة التعاون الجندي المحدودة كل�

تكسير وغربلة آلات مصر

محطم الحديد المحمولة

واستعادة مصنع الذهب تتحرك

تدفق الغسل وسحق خام الحديد خام

تنطوي عملية سحق caco3

مقارنة بين كسارة مخروطية ومحطم مخروط

الصين الماس طاحونة العلامة التجارية

Optimal scheduling method for belt conveyor system in coal mine

2020101 An optimal scheduling method for the belt conveyor system in coal mine considering the silo virtual energy storage capability is proposed in this . The

Coal Industry Conveyor Coal Conveyor Products ASGCO

Coal Conveyor Belt Systems West River Conveyors

20231030 Underground Conveyor Systems. West River Conveyors understands the multiple challenges of underground mining operations. Dust, long runs, and confined

Study and Design of Belt Conveyor System in Coal Mines

201618 Study and Design of Belt Conveyor System in Coal Mines has been written as a part of work and also to foster the use as a handbook for general applications in

Belt Tear Detection for Coal Mining Conveyors MDPI

2022317 In this , we summarized the background and related knowledge of defect detection methods for conveyor belt surfaces in coal mining environments,

Study on Optimization of Coal Truck Flow in Open

2020623 A semicontinuous process system consisting of a single-bucket excavator, truck, crushing station, and belt conveyor is the main coal mining process system of a large-scale hard coal open-pit mine. Through

Optimal operation of coal conveying systems assembled with crushers

2017715 Coal conveying systems are the critical auxiliary systems for coal dependent industries, like steelworks, cement plants, coking plants and coal-fired power

Fresh Approaches for Coal Conveyors Coal Age

2020123 Conveyors serve as the arterial system for coal mines and prep plants. Longwalls and continuous miner sections are often limited by conveyor capacity and

A Faster and Lighter Detection Method for Foreign Objects in Coal Mine

2023710 Coal flow in belt conveyors is often mixed with foreign objects, such as anchor rods, angle irons, en bars, gangue, and large coal chunks, leading to belt tearing, blockages at transfer points, or even belt breakage. Fast and effective detection of these foreign objects is vital to ensure belt conveyors’ safe and smooth operation. This

Industrial Conveyor Belt System COAL

2 Industrial belt Conveyor Parts : 1. Conveyor Belt. The belt conveyor is an endless belt moving over two end pulleys at fixed positions and used for transporting material horizontally or at an inclined up. 2.

Optimal scheduling method for belt conveyor system in coal mine

2020101 How to optimize the operation of coal mine equipment for reducing energy consumption has become a hot issue to the coal mine enterprise. In recent years, the belt conveyor (BC) has become the most common equipment for coal transporting all over the world, and its energy consumption is second only to the mining system.

Advances in coal mining technology and sustainable mining

202311 The overall development of surface coal mining systems can be classified into two different stages. Before 1980, the shovel-train mining system was the major mining technology. During this period, around 10 of the 12 mines used shovel-train as the surface mining system, and only one used shovel truck and the other bucket wheel excavator

Coal Conveyor System SKE Industries

20231027 What is the applications of coal conveyor system? Coal conveyor is mainly used in conveying coal in mine, stockyard, port, in-land terminal, power plant, etc. Now we list some detail applications below: 1. Convey coal in open pit coal mining plant; 2. Transport coal in underground coal mining plant; 3. Stacking, reclaiming, and feeding

Comprehensive Conveyor Belt Systems for Mining CR Mining

Our conveyor belt cleaner systems remove up to 80% of carryback material. We supply a complete cleaning system including: Secondary belt cleaners, made from a variety of materials, including tungsten and polyurethane, to remove fine residual material. Conveyor belt ploughs to remove material on the return side of the conveyor belt, protecting

Belt Tear Detection for Coal Mining Conveyors PMC

2022317 The belt conveyor is the most commonly used conveying equipment in the coal mining industry. As the core part of the conveyor, the belt is vulnerable to various failures, such as scratches, cracks, wear and tear. Yan G. Research on visible light and infrared vision real-time detection system for conveyor belt longitudinal tear. IET Sci

Mining EU Solution INVT Solutions

Mining. According to customers' needs, INVT has provided various belt conveyor, hoist, winch, emulsion pump, mine fans, pumps and other products solutions for the coal mine industry. INVT Medium Voltage VFD Applied to Vent Fan in South Africa. In this case,through introducing INVT GD5000 medium voltage VFD applied to Vent fan in

Belt Tear Detection for Coal Mining Conveyors MDPI

2022317 The belt conveyor is the most commonly used conveying equipment in the coal mining industry. As the core part of the conveyor, the belt is vulnerable to various failures, such as scratches, cracks, wear and tear. Inspection and defect detection is essential for conveyor belts, both in academic research and industrial applications. In this

Transport systems Mining Technology

20211228 Belt conveyor in coal underground mine Drive station B=2250 mm, 4×1250 kW with PIOMA drive units Comprehensive solutions for underground transport system have a significant impact on the efficient production and high economic result of the mine. Transport systems by FAMUR Group fully satisfy and rationalize logistic needs of

Study on Optimization of Coal Truck Flow in Open

2020623 A semicontinuous process system consisting of a single-bucket excavator, truck, crushing station, and belt conveyor is the main coal mining process system of a large-scale hard coal open-pit mine. Through

Fresh Approaches for Coal Conveyors Coal Age

2020123 Longwalls and continuous miner sections are often limited by conveyor capacity and availability. Likewise, prep plants rely on conveyors to deliver raw coal and to transport clean coal and tailings to the refuse impoundment. Most of these operations run 24/7 and, if these systems go down, the mine begins to hemorrhage money.

Research on and Design of an Electric Drive

202369 Conveyor belts are widely used in ore transportation in large-scale mines for their long transportation range, high safety, and strong economic applicability. Coal mine belt conveyors are not only traditional,

A new paradigm for intelligent status detection of belt conveyors

2023531 Currently, it is developing in the direction of large-scale, intelligent[2], [3], and energy-saving[4], [5], [6]. Among them, the intelligence of belt conveyors is an important measure to actively respond to the call for energy conservation and emission reduction, reduce the labor intensity of workers, improve the reliability of system. Methodology

Research of Mine Conveyor Belt Deviation Detection System Based

2021123 The deviation detection system of belt conveyor based on machine vision is mainly composed of video acquisition, image processing and actuators. The video acquisition system mainly uses the mine camera as the image acquisition equipment, and transmits the video image to the industrial control computer of the dispatching room

Mining Free Full-Text Optimising Productivity and Safety of

202182 The open pit mining load and haul system has been a mainstay of the mining industry for many years. While machines have increased in size and scale and automation has become an important development, there have been few innovations to the actual load and haul process itself in recent times. This research highlights some of the

Conveyor systems Transportation Siemens Global Website

20231023 Moving mountains with mining conveyor systems. To meet worldwide demands for raw materials, underground and open-pit mines are being established in increasingly remote areas. Yearly billions of tons of bulk materials such as ore, coal, copper ore, and mining waste have to be moved powerfully, reliably, and efficiently. Mines

A new machine vision detection method for identifying and

2023314 Large foreign object transporting by coal mine conveyor belt may lead to production safety hazards. To reduce safety accidents during coal mining, a large foreign object detection method based on machine vision is proposed in this . An adaptive weighted multi-scale Retinex (MSR) image enhancement algorithm is proposed to

The Recent Technological Development of Intelligent Mining

201781 China’s coal mining technology is still advancing toward the level of the mining technology in Australia, Germany, and the United States. Software is the key of an intelligent mining system, as it allows all procedures along the work face to be controlled intelligently, including shearer cutting, pushing the scraper conveyor, moving

Mining Conveyors West River Conveyors

2 Conveyors for the mining industry vary from small and simple to large, complex systems. Since the mining of different products varies greatly, so do the requirements for conveyor systems, parts and even the services to maintain them. At West River Conveyors, we believe that customization is the key to getting the best conveyor system at the