أرسل لنا رسالة

iron iron ore processing cone crusher

Crushing characteristics and performance evaluation of iron ore

In this study, the crushing process of spherical iron ore particles, constructed by an Apollonian sphere packing (ASP) method, was numerically reproduced in a cone crusher

Crushing characteristics and performance evaluation of iron ore

In this study, the crushing process of spherical iron ore particles, constructed by an Apollonian sphere packing (ASP) method, was numerically reproduced in a cone crusher

Comminution and classification technologies of iron ore

202211 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

(PDF) Comminution in mineral processing ResearchGateThe outlook for iron ore in 2023 Mining Journal

Developments in iron ore comminution and classification

201511 Iron ore crushing and screening. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. About 98% of the mined

: A. Jankovic

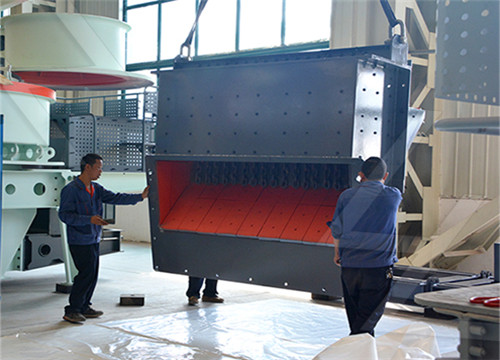

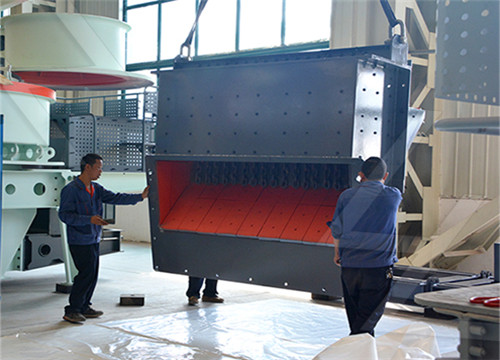

Iron Ore Beneficiation Plant Equipment For Mining Process

202394 It is an 80-100 tph iron ore processing plant. The complete plant consists of the below machines: vibrating feeder, jaw crusher, belt conveyor, cone crusher, double

Influence of Two Mass Variables on Inertia Cone

202124 Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher.

A review of modeling and control strategies for cone crushers

2021815 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used

Crushing characteristics and performance evaluation of iron ore

202311 Request PDF Crushing characteristics and performance evaluation of iron ore in a cone crusher: A numerical study In this study, the DEM (Discrete element

Iron Ore Ore Crushing Solutions

2022222 iron mobile crusher is designed based on the conception of fully adapting various iron crushing condition, eliminating obstacles caused by location,

Metso to deliver 16 cone crushers for Rio Tinto’s iron ore

2023928 Metso to deliver 16 cone crushers for Rio Tinto’s iron ore mines in Australia. Metso Corporation’s press release on September 28, 2023, at 09:00 a.m.

Avoided energy cost of producing minerals: The case of iron ore

2019111 The fundamentals of iron-ore processing and the layouts of processing plants were adapted from Lu Crushing is performed by a gyratory crusher and a cone crusher, with the particle-size output (P80) set as 200 and 60 mm, respectively. A screen with a cut size of 32 mm is placed in a closed circuit with the cone crusher. The screen

flender gearbox for coal crusher MiningQuarry Plant

2013318 Mining crushers mainly include jaw crusher, cone crusher, FLENDER gearbox service, Coal Mill gearboxes. Gulin machine in iron ore processing plant, flender gearbox for coal pulveriser. Gulin provide the flender gearbox for coal pulveriser solution case for you.

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023527 While the cone crusher is more suitable for hard rocks and ores, such as iron ore, granite, pebble. Besides, a cone crusher is not suitable for crushing viscous materials that contain a lot of moisture. 5. Feeding requirements With a cone crusher, the material can be fed directly into the machine until it's full and no silos and feeders are

Cone Crusher Used in Pakistan Iron Ore Mining

2023119 This crusher has a variety of methods, and can match with other equipment quickly. Overall, using this cone crusher for crushing iron ore has the following advantages: 1 It has good performance for crushing iron ore and other minerals which is difficult to process. 2 The finished grain type is good. And the crusher is with high

Iron ore crushing and screening process mpl Ultrafine

202283 Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

Cone Crusher an overview ScienceDirect Topics

Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediate-range size-reducing machines. A schematic diagram of a cone crusher is shown in Fig. 4.6 A.The drive is similar to that of a gyratory crusher. The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the

what are the equipment in iron ore crusher? LinkedIn

2023213 Iron ore crushers are important equipment for iron ore processing. The most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher. Jaw Crusher: A jaw crusher is a

How to Extract Iron from Hematite: Methods and Plants

2023215 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm. This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting.

Chamber Optimization for Comprehensive Improvement of Cone Crusher

2021315 Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the simulation results are basically consistent with the numerical analysis results. Therefore, the working process of the cone crusher is taken

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

what are the equipment in iron ore crusher? LinkedIn

2023213 Iron ore crushers are important equipment for iron ore processing. The most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher. Jaw Crusher: A jaw crusher is a

How to Extract Iron from Hematite: Methods and

2023215 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm.

Chamber Optimization for Comprehensive

2021315 Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Challenges and opportunities in the iron ore crusher market

201988 The jaw crusher is generally used in the crushing process of iron ore. The jaw crusher is a traditional and reliable coarse crushing equipment, and its application range is extremely wide. For high-hardness iron ore, a cone crusher can be used for the secondary crushing equipment. The mpl short-headed cone crusher can achieve a fine

Iron Mining Process Equipment Flow Cases JXSC

202392 Iron Ore Mining Process. 1. Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will be transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for

iron ore processing-MINERAL PROCESSING-Crusher,Cone Crusher

The iron ore with industrial application mainly consists of magnetite ore, hematite ore and martite; secondly in siderite, limonite, etc. The iron ore is one of the most important raw materials for steel production enterprise. The grade of iron ore refers to the mass fraction of iron element in iron ore, say, the iron content. For example, if

Types of Crushers: What You Need to Know Machinery

The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller bottom output hole of the cone. While the cone does not move, an interior crushing movement is created by a revolving shaft on a vertical rod.

The 4 Types Iron Ore Crushing Stations You Must Know

2023331 Generally, jaw crusher is used as coarse crushing equipment in small-scaled iron ore processing plants or quarries. 3. The gyratory crusher adopt continuous crushing, with its outstanding advantages of high productivity, high crushing ratio, up to 6-9.5, and in some cases, the crushing ratio can even reach to 13.5, and stable operation

Developments in iron ore comminution and classification

201511 Iron ore crushing and screening. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. About 98% of the mined

Iron Ore Beneficiation Plant Equipment For Mining Process

202394 It is an 80-100 tph iron ore processing plant. The complete plant consists of the below machines: vibrating feeder, jaw crusher, belt conveyor, cone crusher, double

Influence of Two Mass Variables on Inertia Cone

202124 Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher.

A review of modeling and control strategies for cone crushers

2021815 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used

Crushing characteristics and performance evaluation of iron ore

202311 Request PDF Crushing characteristics and performance evaluation of iron ore in a cone crusher: A numerical study In this study, the DEM (Discrete element

Iron Ore Ore Crushing Solutions

2022222 iron mobile crusher is designed based on the conception of fully adapting various iron crushing condition, eliminating obstacles caused by location,

Metso to deliver 16 cone crushers for Rio Tinto’s iron ore

2023928 Metso to deliver 16 cone crushers for Rio Tinto’s iron ore mines in Australia. Metso Corporation’s press release on September 28, 2023, at 09:00 a.m.

Avoided energy cost of producing minerals: The case of iron ore

2019111 The fundamentals of iron-ore processing and the layouts of processing plants were adapted from Lu Crushing is performed by a gyratory crusher and a cone crusher, with the particle-size output (P80) set as 200 and 60 mm, respectively. A screen with a cut size of 32 mm is placed in a closed circuit with the cone crusher. The screen

flender gearbox for coal crusher MiningQuarry Plant

2013318 Mining crushers mainly include jaw crusher, cone crusher, FLENDER gearbox service, Coal Mill gearboxes. Gulin machine in iron ore processing plant, flender gearbox for coal pulveriser. Gulin provide the flender gearbox for coal pulveriser solution case for you.

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023527 While the cone crusher is more suitable for hard rocks and ores, such as iron ore, granite, pebble. Besides, a cone crusher is not suitable for crushing viscous materials that contain a lot of moisture. 5. Feeding requirements With a cone crusher, the material can be fed directly into the machine until it's full and no silos and feeders are

Cone Crusher Used in Pakistan Iron Ore Mining

2023119 This crusher has a variety of methods, and can match with other equipment quickly. Overall, using this cone crusher for crushing iron ore has the following advantages: 1 It has good performance for crushing iron ore and other minerals which is difficult to process. 2 The finished grain type is good. And the crusher is with high

Iron ore crushing and screening process mpl Ultrafine

202283 Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

Cone Crusher an overview ScienceDirect Topics

Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediate-range size-reducing machines. A schematic diagram of a cone crusher is shown in Fig. 4.6 A.The drive is similar to that of a gyratory crusher. The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the

what are the equipment in iron ore crusher? LinkedIn

2023213 Iron ore crushers are important equipment for iron ore processing. The most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher. Jaw Crusher: A jaw crusher is a

How to Extract Iron from Hematite: Methods and Plants

2023215 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm. This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting.

Chamber Optimization for Comprehensive Improvement of Cone Crusher

2021315 Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the simulation results are basically consistent with the numerical analysis results. Therefore, the working process of the cone crusher is taken

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

what are the equipment in iron ore crusher? LinkedIn

2023213 Iron ore crushers are important equipment for iron ore processing. The most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher. Jaw Crusher: A jaw crusher is a

How to Extract Iron from Hematite: Methods and

2023215 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm.

Chamber Optimization for Comprehensive

2021315 Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Challenges and opportunities in the iron ore crusher market

201988 The jaw crusher is generally used in the crushing process of iron ore. The jaw crusher is a traditional and reliable coarse crushing equipment, and its application range is extremely wide. For high-hardness iron ore, a cone crusher can be used for the secondary crushing equipment. The mpl short-headed cone crusher can achieve a fine

Iron Mining Process Equipment Flow Cases JXSC

202392 Iron Ore Mining Process. 1. Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will be transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for

iron ore processing-MINERAL PROCESSING-Crusher,Cone Crusher

The iron ore with industrial application mainly consists of magnetite ore, hematite ore and martite; secondly in siderite, limonite, etc. The iron ore is one of the most important raw materials for steel production enterprise. The grade of iron ore refers to the mass fraction of iron element in iron ore, say, the iron content. For example, if

Types of Crushers: What You Need to Know Machinery

The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller bottom output hole of the cone. While the cone does not move, an interior crushing movement is created by a revolving shaft on a vertical rod.

The 4 Types Iron Ore Crushing Stations You Must Know

2023331 Generally, jaw crusher is used as coarse crushing equipment in small-scaled iron ore processing plants or quarries. 3. The gyratory crusher adopt continuous crushing, with its outstanding advantages of high productivity, high crushing ratio, up to 6-9.5, and in some cases, the crushing ratio can even reach to 13.5, and stable operation