أرسل لنا رسالة

the component of double roll crusher

New insights into double roll crushing ScienceDirect

General view of the roll crusher with the main components (Thiere, 2020). ((1) pulley with flywheel, (2) fixed roll bearing block, (3) hydraulic cylinder with cross circuit, (4) floating roll bearing block, (5) gap adjustment).

Dynamics in double roll crushers ScienceDirect

201741 Knowledge on realistic magnitude and dynamic characteristics of those forces is essential to improve the design of machine components such as rolls, shafts,

The double-roll crusher model applied to a two-component feed material

198351 This test was performed to provide data to check the twocomponent roll crusher model for a size distribution of two-component feed materialAs with the tests of

Dynamics in double roll crushers ScienceDirect

201741 A discrete element method (DEM) model of the crushing process of a toothed double-roll crusher (TDRC) is established using the bonded particle model. DEM

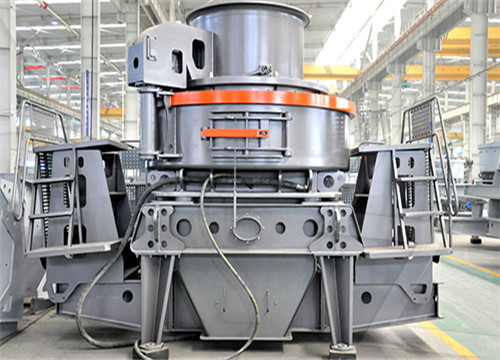

Double Roll Crusher Henan Deya Machinery Co., Ltd.

Double Roll Crusher Working PrincipleApplication of Double Roll CrusherMeaning of The Model

Roll crushers, or crushing rolls, or double roll crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. They still have a useful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum, phosphate, and soft iron ores. The moddeyamachinery

(PDF) The Influence of the Structure of Double

2018117 A discrete element method (DEM) model of the crushing process of a toothed double-roll crusher (TDRC) is established using the bonded particle model.

Roll Crusher an overview ScienceDirect Topics

Roll Crusher. For a given reduction ratio, single-roll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass,

Dynamics in double roll crushers Science

Double roll crushers Comminution HPGR Self similarity abstract Double roll crushers (DRC) have the highest throughputs among primary crushers. In the oil sands, the hourly

The double-roll crusher model applied to a two-component

198351 The double-roll crusher model is extended and validated for a feed comprising two separable components. References (6) L.G. Austin et al. Int. J. Miner.

Modeling of coal breakage in a double-roll crusher

2012121 A discrete element method (DEM) model of the crushing process of a toothed double-roll crusher (TDRC) is established using the bonded particle model.

Modeling of particle breakage in a smooth double roll crusher

2009216 Rogers (1983) extended the model for two component feed. The objective of the present stone is to find out a generalized selection function for roll crusher that can incorporate particle properties so that for any particle, whose properties are known, product size distribution after breakage can be predicted.

McLanahan Roll Crushers

They can be used in coal, salt, coke, glass, and trona operations, among others. Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing a cubicle product at high capacity.

The Differences Between Double Roll Crushers

2020324 Cost. With the design differences also comes cost differences. The Double Roll Crusher is the more cost-effective option of the two. The main differences that make up the majority of the cost

Roll Crusher HRC

For industrial beneficiation of primary and secondary raw materials, selection of the most appropriate crushing method plays a key role in the production of specific grain sizes, shapes and surfaces, or to break down multi-component materials. The selected crusher must conform to today’s stringent requirements for processing rocks, ores and

Analysis of vertical roller mill performance with

2022531 Li et al. (2019) discovered the effects of rotation speed and structure of crushing rolls on the performance of a toothed double-roll crusher. The results showed that when the roll’s speed was relatively high, more cracks could be created to release the increasing strain energy, generating more fractions of small sizes in the products.

Double Roll Crusher TG 2000 ERWEKA GmbH

1 Double Roll Crusher TG 2000 ERWEKA GmbH. Get a quote! Double Roll Crusher with two driven rollers running in opposing directions from the inside to the outside. The rollers are 70 mm long and made of stainless steel. They are equipped with teeth to produce a powerful grinding action by forcing the material against a series of braking combs.

AR 403 ERWEKA PDF Catalogs Technical Documentation

The maximum capacity of the double roll crusher is 20 kg / hour. An emergency stop helps to prevent injuries. Double Roll Crusher with two driven rollers running in opposing directions from the inside to the outside. All components are either covered with hard chrome, or made of stainless steel AISI 304 or acrylic glass for the front door

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015410 Figure 4: Double Roll Crusher Figure 5: Rotary Breaker Crusher Figure 6: Impact Crusher Grinding jib of crushers Reduction in thickness due Continuous coal flow Friction between coal and to wearing of surface component Grinding jib of crushers Development of cracks, Impact of coal Crack generated from holes the holes for fixing of

Roll Crushers TAKRAF TAKRAF GmbH

25: 2,500 mm pitch circle roll diameter. 37: 3,700 mm roll length. Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing applications at up to 1,500 kW of motor power. Each gearbox is manufactured and tested at our workshop in Lauchhammer, Germany.

Rolls Crushers Smooth Roll Crushers, Wroking, Construction

20221113 The vertical component of forces T and N are opposed. Force N sin α tends to expel the particle from the rolls and force T cos α tends to draw the particle between the rolls. Single Roll Crusher provides up to a 6:1 ratio of reduction and double roll crusher 4:1. What is the capacity of a roll crusher? Max. Feed Capacity LC-13: 3,000lb (1

Roll Crushers TAKRAF TAKRAF GmbH

25: 2,500 mm pitch circle roll diameter. 37: 3,700 mm roll length. Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing

Roll Crushers Williams Crusher

Contact us today to discuss your primary crusher application with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. Contact Us.

Dynamics in double roll crushers ScienceDirect

201741 As a result, the forces acting in a double roll crusher could be much higher, at least locally, as one would expect for normal single particle comminution. This should be true even if the DRC is, as usual, starvation fed with just about 15 per cent of the crushing gap filled with solids. 3. Crushing and bearing forces.

Rolls Crushers Smooth Roll Crushers, Wroking, Construction

20221113 The vertical component of forces T and N are opposed. Force N sin α tends to expel the particle from the rolls and force T cos α tends to draw the particle between the rolls. Single Roll Crusher provides up to a 6:1 ratio of reduction and double roll crusher 4:1. What is the capacity of a roll crusher? Max. Feed Capacity LC-13: 3,000lb (1

The double-roll crusher model applied to a two-component

198351 The double-roll crusher model is extended and validated for a feed comprising two separable components. References (6) L.G. Austin et al. Int. J. Miner. Process. (1980) L.G To represent the particle behaviors and to predict the product size distributions of coal breakage products by a double-roll crusher, a new combined

How To Design Roll Crusher PDF PDF Belt (Mechanical)

202037 MACHINE DESIGN 2 59 2012 [DOUBLE ROLL CRUSHER DESIGN] Table 1.1 Factors of safety. Table 9 Century Spring Catalog. MACHINE DESIGN 2 60 2012 [DOUBLE ROLL CRUSHER DESIGN] Figure AF 15 Stress Factor. MACHINE DESIGN 2 61 2012 [DOUBLE ROLL CRUSHER DESIGN] Table AT 17 Mechanical Properties of Wire

Coal comminution and sizing ScienceDirect

201311 Schematic of roll crushers for coal breakage: (a) single-roll crusher; (b) double-roll crusher. Single-roll crushers may be either feeder-breakers, or conventional rolls. The rolls on feeder-breakers resemble the cutting head of continuous coal mining machines. Feeder-breakers have very high capacities of up to 2000 tons/h, and are mainly

McLanahan Double Roll Crushers

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1. The simplified design gives these units excellent reliability and requires very little maintenance. The crushers are designed with built-in tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the

Understanding the Double Roll Crusher and Its Applications

2023223 This article explores the benefits and uses of double roll crushers in the mining industry. It provides an in-depth analysis of the components, operating principles, and various applications of double roll crushers. Additionally, it compares the advantages and limitations of double roll crushers with other types of crushers commonly used in mining