أرسل لنا رسالة

what is the size and function of cement mill

what is the size and function of cement mill

Cement Mill,Cement Mill Price,Cement Miller- China, The cement mill is The key equipment for furTher lining boards installed with different sizes of and Energy Saving Functions of cement mills; Go to Product Center

Cement Mill Cement Ball Mill Vertical Cement

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement

The cement mill Understanding Cement

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the

Review on vertical roller mill in cement industryits

202111 The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier. Material is ground till desired Blaine is achieved and then final

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Cement mill also called cement grinding mill, is a cement grinding machine used in cement plant for raw materials, cement clinker, and coal grinding. The cement mill produced by

Cement Milling Understanding Cement

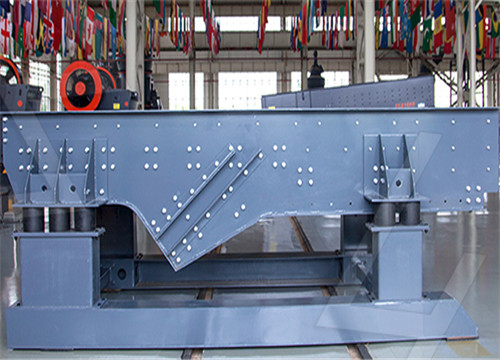

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding

Modeling of energy consumption factors for an industrial cement

202259 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's

Ball Mill an overview ScienceDirect Topics

The minimal magnitude of ball size is calculated in millimeters from the equation: where db.max is the maximum size of feed (mm); σ is compression strength (MPa); E is

A scale-up and design basis of continuous tube mills in cement

202031 Relation between degree of size reduction and mill scale-up variables for cement mills in open and closed circuits.

Analysis of grinding media effect on specific breakage rate function

2015101 A full-scale three-compartment ® cement grinding ball mill with dimensions of Ø3.5 × L10 operating in open circuit was sampled to analyse the grinding media effect on specific breakage rate function of particles.Size reduction performance of the ball mill was evaluated with respect to the applied grinding media size.

Vertical Roller Mill VS Roller Press in Cement

With the continuous development of grinding technology, there are two kinds of cement grinding equipment with lower energy consumption, one is vertical roller mill, and the other is roller press. The two types of equipment are

Cement Milll Separator Cyclone Air Separator in Cement Plant

Product Name: cement mill cyclone air separators. Capacity: 10 250 TPD. Condition: brand new. Airflow: 16000 240000 m3/h. SEND INQUIRY. Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants. The function of the separator is to separate

Modeling of energy consumption factors for an industrial cement

202259 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is

(PDF) Effects of Mill Speed and Air Classifier Speed on

2021629 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two

Ball MillRoller Press for Cement Grinding Process

The combined grinding system of roller press and ball mill. With the invention of V-type separator, the combined grinding system composed of roller press and ball mill has been developed to further reduce the energy consumption of the cement grinding process. In this system, the ground materials from the roller press is first processed by the

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal

How To Measure Your Cement Mill And Cement Classifier? AGICO CEMENT

2020121 With the increase of cement mill specifications and the requirement of energy saving, high yield, and high quality of cement grinding plant, the closed-circuit grinding is an inevitable trend of cement grinding unit.The essential equipment of a closed-circuit grinding system is a cement classifier, also known as a cement separator.The

An energy based comparison of vertical roller mills and tumbling mills

2015310 The vertical roller mill equipped with an internal classifier is often said to be more energy efficient than tumbling mills working on the same material and the same size step (e.g. Gerold et al., 2012). It is long established in the cement industry and gains more and more importance in the industrial mineral and iron ore sectors.

TipsNotes for How to Maintain Your Bag Filter AGICO Cement

Bag Filter Maintenance Notes. Bags in a bag filter. Before maintaining or repairing the bag filter, its power supply and air source must be cut off, and the airbag should be under normal pressure. During the maintenance and repair of the bag filter, the dust inside shall be cleaned repeatedly to ensure that there is no dust inside.

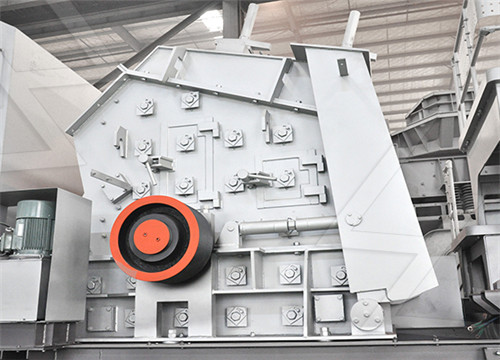

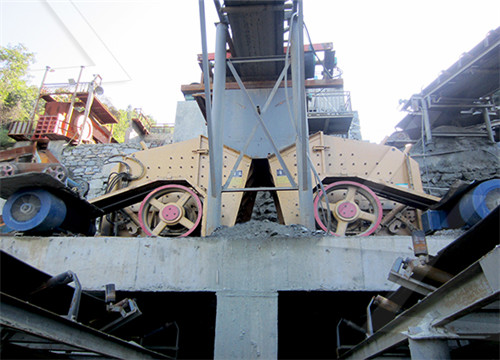

Impact Crusher an overview ScienceDirect Topics

Impact Crusher. The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

Coal utilisation in the cement and concrete industries

201311 The mill itself will likewise be designed to handle a maximum physical size which varies from mill type to mill type. For example, in the case of Vertical Spindle (Roller) type mills, the top size typically ranges from 25 to 50 mm (1–2 in.) depending on the mill geometry and rolling element size. Typically, the limitation is 5% of the

The cement mill Understanding Cement

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. The drum is generally divided into two or three chambers, with different

Cement fineness. Closed circuit cement mill by A.Sen

Aug 20, 2020. Closed circuit cement mill. The strength development of concrete is the result of the chemical reaction of water with cement particles. The reaction always starts at the surface of the cement particles. Thus larger the surface available for reaction, greater is the rate of hydration and strength development.

PROCESS CONTROL FOR CEMENT GRINDING IN

20171027 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and