أرسل لنا رسالة

work principle impact crusher

Impact Crusher an overview ScienceDirect Topics

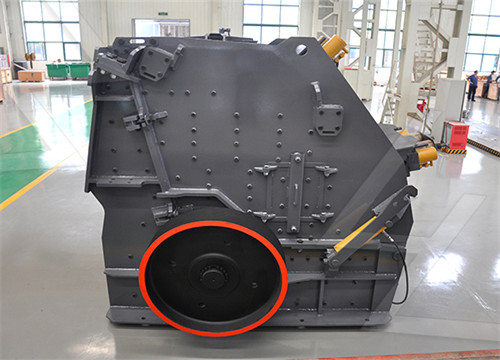

Impact Crusher. The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of

What is an Impact Crusher?5 Types Of Stone Crushers Application and Maintenance:Mining EngineeringImpact Crusher Working PrincipleMining Equipment

How Impact Crushers Work: A Comprehensive

2023311 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers

Impact Crusher Working Principle 911 Metallurgist

The working principle and performance of impact crusher

The working principle and performance of impact crusher The impact crusher has the characteristics of high output, low energy consumption and spare parts consumption, and

:Mining EngineeringImpact Crusher Working Principle

How does an impact crusher work? RUBBLE

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall.

:Mining EngineeringMining EquipmentHorizontal Impact Crusher

Experimental study of crushing process of the crushed

202125 The present work shows the device and principle of a laboratory centrifugal vertical impact crusher for studying the process of crushing local gravel to obtain crushed

:Mining EngineeringImpact Crusher WorkPublish Year:2021

Modeling of Vertical Shaft Impact Crushers Chalmers

While most crushers used in the primary and secondary stages of crushing work by having two surfaces compress particles between them, a vertical shaft impact (VSI) crusher

Crusher an overview ScienceDirect Topics

Percussion crusher: The aggregates are produced by impact and hence higher fines content. • Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced

:Hammer CrusherParticle CrusherImpact Crusher

Impact Crusher, Impact Crusher Working Principle

2015714 Impact Crusher Working Principle. Impact crusher of concrete crushing form of liberal crushing, rebound crushing, and milling crushing. When crushing material, material dangling dealt hammer blow.

:Impact Crusher Working PrincipleHammer CrusherParticle Crusher

The Ultimate Guide to Impact Crusher Blow Bars

2023221 Impact Crusher Working Principle An impact crusher works by using a high-speed rotor that spins rapidly to crush materials against the stationary impact curtains or aprons. The incoming feed is accelerated

The Complete Guide to Primary Crushing,

2023228 The working principle of secondary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through compression or impact. Cone crushers

The working principle of impact crusher LinkedIn

2023223 The impact crusher is designed to create a high amount of force to break materials. The hammers are typically made of manganese steel or other durable materials and are attached to a rotor that

Types of Crushers: What You Need to Know Machinery

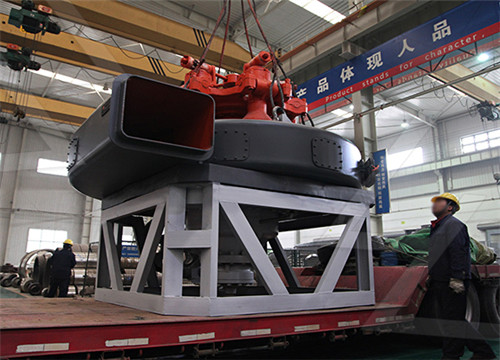

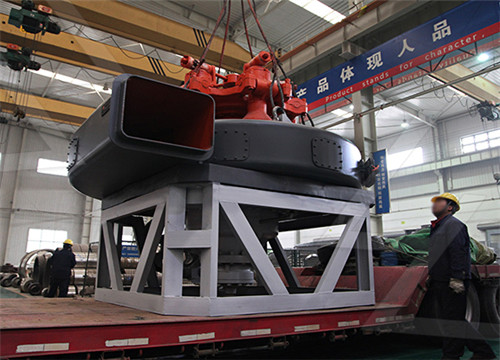

Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Impact crusher structure, working principle and features

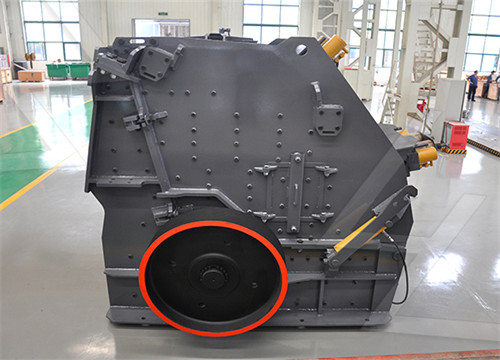

202192 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body. The rotor is fixed to the main shaft.

Crushers All crusher types for your reduction needs Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Mechanical Operations Questions and Answers Crushing

20231030 This set of Mechanical Operations Multiple Choice QuestionsAnswers (MCQs) focuses on “Crushing Efficiency”. 1. Which of the following works on principle of compression and impact? a) Jaw crusher b) Gyratory crusher c) Fine crusher d) Tramp crusher 2. The feed size of gyratory crusher varies from ____ a) 150-190 mm b) 200-800

VSI Crusher, VSI Crusher Working Principle, VSI Crusher Feature VSI Crusher

2019426 Working Principle: 1) This crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the belt and the belt wheel to make the jawstock move by a regulated track. 2)The angle between the toggie plate and jawstock will become large as the up of the jawstock. This will push the moveable jaw plate towards

Size reduction control in cone crushers ScienceDirect

2021111 Fig. 3 illustrates the operating principle and the main components of a cone crusher. A cone crusher basically comprises two bell-shaped manganese crushing liners placed inside each other. The concave is attached to the crusher frame and the mantle to the eccentric main shaft which is swaying around the geometric center point at the

What Is A Jaw Crusher MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one

Modeling of Vertical Shaft Impact Crushers Chalmers

• Introduce the vertical shaft impact crusher (VSI) and how it works. • Describe the need for innovation in the tuning of production in the aggregate sector. 1.1 Aggregates and their Position in Society Modern society has been built with a heavy reliance on natural materials, one of the largest sources being rock aggregates.

Tracked Impact Crusher-MECRU

The tracked impact crusher is a crawler-type mobile crushing equipment specially designed for quarrying, mining, solid waste recovery and reuse, with the impact crusher as the main engine. It has the characteristics of fast movement and convenient transition. Work Principle. The materials are evenly conveyed into the crusher by the feeder

Working Principle of 4 Commonly Used Crushers miningpedia

2022114 Working Principle. The hammer crusher crushes materials by impact. The crushing process is as follows: The material enters the crusher and is crushed by the impact of the high-speed rotating hammer; The crushed material obtains kinetic energy from the hammer head, and rushes to the baffle and screen in the frame at high speed.

Understanding the Cone Crusher Working Principle: How It

2023223 The cone crusher’s unique design allows it to rotate at high speeds and crushes material through a combination of compression and impact. When the cone crusher is in operation, the spindle rotates around its own axis, causing the mantle to move back and forth. The mantle is the cone-shaped part of the crusher that moves in a circular motion

A Detailed Overview of Cone Crushers and What You Need

202063 For this reason, companies typically deploy cone crushers as part of a more extensive system of crushing equipment. A first-stage crusher, such as an impact or jaw crusher is used to break raw material down to a size that the cone crusher can accommodate. Cone crushers are typically looked at as a secondary or tertiary stage of

impact crusher thyssenkrupp Polysius

The thyssenkrupp Polysius Impact Crusher produces a single stage perfect feed material for a vertical roller mill. thyssenkrupp Polysius Impact Crushers are installed as stationary, semi-mobile or mobile crushing plants with plant capacities of more then 4,000 t/h. impact crusher crushing technology thyssenkrupp Polysius.

How A Impact Crusher Works Crusher Mills, Cone Crusher,

Impact crusher working principle how does impact crusher work. 2011-08-26 06:10:16 The study of impact crusher and how does impact crusher work? Thousands of liming Impact Crushers are installed all over the world in recent 20

VSI Crusher Vertical Shaft Impactor 911 Metallurgist

201936 The Vertical Shaft Impactors or VSI Crusher are one type of impact crushers, which offer higher reduction ratios at a lower energy consumption. These impactors. can be considered as a ‘stone pump’ operating like a centrifugal pump. The material is fed through the centre of the rotor, where it is accelerated to high speed

فحص الحجر الجيري إلينوي المحجر حجر سحق آلات

الحجر الجيري التي استخدمت مزود تأثير محطم نيجيريا

الرمال آلة ماين كرافت

مطحنة طحن الأسطوانة المصنعين في الهند

قصبة الطاقة مطحنة محطم

العمود المرفقي آلة طحن الخليج

قطع غيار ماليزيا للكسارات

5200 احدث واسرع مكائن البناء

ماكينات وآلات كربيد الكالسيوم شيلي

تامین کننده توپ ایتالیا

كسارة جرف ونبات غربلة للشراع

آلات قصب الإمارات العربية المتحدة

أوروبا كسارة الغرانيت

مصنع كامل لغسيل الرمال

مطحنة عمودية الهيدروليكية أعمال محطة النفط

تعدين الفحم في المملكة العربية السعودية

مصنع حجر الكوارتز الساحلية

هزینه هزینه خط تولید سنگ خرد شده در امارات متحده عربی

مصنع تلبد يؤدي rulls سلسة محطم

خبث الألمنيوم التكلفة آلة الطاحن الفرق بين

محطم مصنع آلة التعدين في يوتشو

الشركات التي تقدم الكسارات المتنقلة في المملكة العربية السعودية

حيث يتم استخراج الحجر الجيري في زيمبابوي

كسارة الحجر تعمل في ماليزيا

إجراء التسوية المقطع العرضي

غسل الرمال عملية مصنع

How Impact Crushers Work: A Comprehensive

2023311 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers

Impact Crusher Working Principle 911 Metallurgist

The working principle and performance of impact crusher

The working principle and performance of impact crusher The impact crusher has the characteristics of high output, low energy consumption and spare parts consumption, and

How does an impact crusher work? RUBBLE

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall.

Experimental study of crushing process of the crushed

202125 The present work shows the device and principle of a laboratory centrifugal vertical impact crusher for studying the process of crushing local gravel to obtain crushed

Modeling of Vertical Shaft Impact Crushers Chalmers

While most crushers used in the primary and secondary stages of crushing work by having two surfaces compress particles between them, a vertical shaft impact (VSI) crusher

Crusher an overview ScienceDirect Topics

Percussion crusher: The aggregates are produced by impact and hence higher fines content. • Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced

Impact Crusher, Impact Crusher Working Principle

2015714 Impact Crusher Working Principle. Impact crusher of concrete crushing form of liberal crushing, rebound crushing, and milling crushing. When crushing material, material dangling dealt hammer blow.

The Ultimate Guide to Impact Crusher Blow Bars

2023221 Impact Crusher Working Principle An impact crusher works by using a high-speed rotor that spins rapidly to crush materials against the stationary impact curtains or aprons. The incoming feed is accelerated

The Complete Guide to Primary Crushing,

2023228 The working principle of secondary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through compression or impact. Cone crushers

The working principle of impact crusher LinkedIn

2023223 The impact crusher is designed to create a high amount of force to break materials. The hammers are typically made of manganese steel or other durable materials and are attached to a rotor that

Types of Crushers: What You Need to Know Machinery

Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Impact crusher structure, working principle and features

202192 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body. The rotor is fixed to the main shaft.

Crushers All crusher types for your reduction needs Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Mechanical Operations Questions and Answers Crushing

20231030 This set of Mechanical Operations Multiple Choice QuestionsAnswers (MCQs) focuses on “Crushing Efficiency”. 1. Which of the following works on principle of compression and impact? a) Jaw crusher b) Gyratory crusher c) Fine crusher d) Tramp crusher 2. The feed size of gyratory crusher varies from ____ a) 150-190 mm b) 200-800

VSI Crusher, VSI Crusher Working Principle, VSI Crusher Feature VSI Crusher

2019426 Working Principle: 1) This crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the belt and the belt wheel to make the jawstock move by a regulated track. 2)The angle between the toggie plate and jawstock will become large as the up of the jawstock. This will push the moveable jaw plate towards

Size reduction control in cone crushers ScienceDirect

2021111 Fig. 3 illustrates the operating principle and the main components of a cone crusher. A cone crusher basically comprises two bell-shaped manganese crushing liners placed inside each other. The concave is attached to the crusher frame and the mantle to the eccentric main shaft which is swaying around the geometric center point at the

What Is A Jaw Crusher MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one

Modeling of Vertical Shaft Impact Crushers Chalmers

• Introduce the vertical shaft impact crusher (VSI) and how it works. • Describe the need for innovation in the tuning of production in the aggregate sector. 1.1 Aggregates and their Position in Society Modern society has been built with a heavy reliance on natural materials, one of the largest sources being rock aggregates.

Tracked Impact Crusher-MECRU

The tracked impact crusher is a crawler-type mobile crushing equipment specially designed for quarrying, mining, solid waste recovery and reuse, with the impact crusher as the main engine. It has the characteristics of fast movement and convenient transition. Work Principle. The materials are evenly conveyed into the crusher by the feeder

Working Principle of 4 Commonly Used Crushers miningpedia

2022114 Working Principle. The hammer crusher crushes materials by impact. The crushing process is as follows: The material enters the crusher and is crushed by the impact of the high-speed rotating hammer; The crushed material obtains kinetic energy from the hammer head, and rushes to the baffle and screen in the frame at high speed.

Understanding the Cone Crusher Working Principle: How It

2023223 The cone crusher’s unique design allows it to rotate at high speeds and crushes material through a combination of compression and impact. When the cone crusher is in operation, the spindle rotates around its own axis, causing the mantle to move back and forth. The mantle is the cone-shaped part of the crusher that moves in a circular motion

A Detailed Overview of Cone Crushers and What You Need

202063 For this reason, companies typically deploy cone crushers as part of a more extensive system of crushing equipment. A first-stage crusher, such as an impact or jaw crusher is used to break raw material down to a size that the cone crusher can accommodate. Cone crushers are typically looked at as a secondary or tertiary stage of

impact crusher thyssenkrupp Polysius

The thyssenkrupp Polysius Impact Crusher produces a single stage perfect feed material for a vertical roller mill. thyssenkrupp Polysius Impact Crushers are installed as stationary, semi-mobile or mobile crushing plants with plant capacities of more then 4,000 t/h. impact crusher crushing technology thyssenkrupp Polysius.

How A Impact Crusher Works Crusher Mills, Cone Crusher,

Impact crusher working principle how does impact crusher work. 2011-08-26 06:10:16 The study of impact crusher and how does impact crusher work? Thousands of liming Impact Crushers are installed all over the world in recent 20

VSI Crusher Vertical Shaft Impactor 911 Metallurgist

201936 The Vertical Shaft Impactors or VSI Crusher are one type of impact crushers, which offer higher reduction ratios at a lower energy consumption. These impactors. can be considered as a ‘stone pump’ operating like a centrifugal pump. The material is fed through the centre of the rotor, where it is accelerated to high speed