أرسل لنا رسالة

function of screening plant in iron ore

Comminution and classification technologies of iron ore

202211 Abstract Hematite and magnetite, the two predominant iron ores, require different processing routes. High-grade hematite direct shipping ores generally only require crushing and screening to meet the size requirements of lump (typically between 6 and

Processing of Magnetite Iron Ores–Comparing Grinding OptionsThe 4 Types Iron Ore Crushing Stations You Must Know Iron ore classification Process productivityComminution modeling using mineralogical properties of iron (PDF) Mineral and Technological Features of Magnetite

Advances in screening technology in the mining sector

1 Introduction2 Growing Demands on Screening Machines3 Screening Machines For Iron Ore and Coal5 Developments in Fine screen Technology6 Prospects

The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. While good quality magnetite is now dry-processed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations. The fineness requirements depend on which me...

Impact of key parameters on the iron ore pellets roller screening

2022610 Thomazini has reported, through discrete element analysis (DEM), the screening efficiency of an iron ore pelletizing plant using a single deck roller screen

Impact of key parameters on the iron ore pellets roller

Abstract. The roller screening process is an important step in the iron ore pellets production. This step is intrinsically linked to the balling production and the induration machine.

Ore Beneficiation an overview ScienceDirect Topics

Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore,

Screening Plant an overview ScienceDirect Topics

The iron ore lump obtained from ROM crushing and screening plants will continue to break down into − 6.3 mm particles during material handling from the product screen to

Optimization of Solids Concentration in Iron Ore Ball Milling

2019618 One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The stone

(PDF) Beneficiation and flowsheet development of

2020121 PDF In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied. The Run of Mine (R.O.M) sample Find, read and cite all the research you

AI Free Full-Text Monitoring of Iron Ore Quality

2022615 Currently, one of the main ways to evaluate the quality of iron ore produced at any stage of the production chain of mining companies is through chemical analysis methodologies of samples, which are

Existing and New Processes for Beneficiation of

202028 Cliff’s Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant, has been applied to produce pellet grade

Iron ore beneficiation: an overview ScienceDirect

202311 Dry processing of iron ore: In dry processing of iron ore, ROM is generally crushed below 40 mm through three-stage crushing and thus segregated by screening into 10–40 and −10 mm fractions. For softer ore, tumbler index is generally low and hence lump ore is crushed below 10 mm to produce 100% fine product. Yield from the plants has

Existing and New Processes for Beneficiation of

202028 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very

Characterization and Beneficiation of Dry Iron Ore Processing Plant

2018918 The generation of iron ore fines in dry processing plant of Khondbond region, India is about 30–40% of the total feed. The iron ore fine assayed 58.73% Fe (T), 5.54% Al 2 O 3, 6.6% SiO 2, and 4.37% LOI. Particle size distribution of fines showed that 50% (by weight) of material are below 1800 μm.

Coal use in iron and steel metallurgy ScienceDirect

201311 Contrary to the almost pure iron of meteoric origin, manufactured iron (pig iron or hot metal) and steel are ferrous alloys of iron with carbon and further impurities (Fig. 12.3).Carbon lowers the melting point of iron from 1538 °C in pure iron to 1147 °C in the eutectic with 4.3% C. Carbon content in steel is up to 2.14 % that corresponds to

Fugitive dust emission control study for a developed smart

202151 The DFDSS was installed in a crushing and screening plant of an iron ore mine in India. Performance study indicted fugitive dust emission concentration values ranged from 354 to 7040 μg m−3, which was reduced to 91–300 μg m −3 after installation of DFDSS. The reduced values were within the permissible limit of 1200 μg m −3 at a

McLanahan breaks the cycle for scrubbing and screening

201966 Original equipment manufacturer (OEM) McLanahan offers a machine that combines both rotary scrubbing and screening functions into a single unit. By combining these two essential functions, the

(PDF) ORE SEPARATION BY SCREENING ResearchGate

201733 Sieving is a process of separation of the ore material into multiple grades by particle size [1]. The screen is a vibrating mining machine, that is driven to motion by a rotating of unbalanced

Crushing Plant Design and Layout Considerations 911

2016224 Ore Characteristics Ore characteristics are a critical element in both crusher selection and plant design. Dry ores require greater provisions for dust suppression and collection, including dust enclosures around screens, sealing on conveyor skirts, and vacuum and wash-down systems. Wet, sticky ores can

(PDF) Iron Ore Sintering: Raw Materials and Granulation

20161028 Abstract and Figures. Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slag-forming elements and coke. The purpose of sintering is to obtain a product

A Mine-to-Crusher Model to Minimize Costs at a Truckless Open-Pit Iron

2022818 Innovation has an important role in improving the productivity, safety and sustainability of mining operations. Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies. The innovative

Developments in iron ore comminution and classification

201511 The largest iron ore company in world, Vale, is developing S11D project, located in the Amazon region of Northern Brazil (Carajás), which is expected to produce 90 million Mtpa of iron ore (Carter, 2011). In designing the innovative, modular ore crushing and screening plant for SD11, Vale was faced with the challenge of coping with the region

Screening, Separation and Vibration Mining Technology

Screening, separation and vibration equipment for the mining industry. Screening, classifying and separation are integral to ore processing, metals and minerals extraction, and controlling the final product quality in any mining and processing operation. Adopting efficient screening and separation solutions can increase yield and productivity

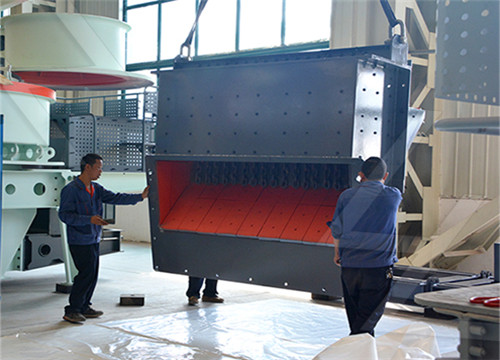

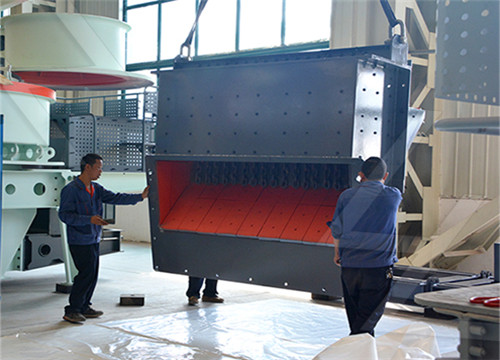

Mobile Screening Station-Multi-Functions, High

2023923 Vibrating Screen: 3YZS2160. Compared with the traditional fixed screening plant, the mobile screening plant has the characteristics of high mobility, strong flexibility, wide adaptation, and

Simulation of Classification and Stratification in Double

202354 The experiment consisted in feeding 10 kg of freshly produced green pellets to the screen during a period of 30 s. The motion of pellets inside the screen was then registered using a high-speed camera (SONY RX-10 IV–Fig. 1), capable of capturing videos at 960 fps. 2.2 Base Case Double-deck Industrial Roller Screen. The base case for the

Minerals Free Full-Text Sensor-Based Ore Sorting

201978 Graphical Abstract. 1. Introduction. Sensor-based ore sorting is gaining increased attention both within and outside the mining industry, as it is leaving the state of pilot plant scale and technology road-mapping, and an increasing amount of equipment is installed in high-capacity production scale environments.

Iron Ore an overview ScienceDirect Topics

Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig. 13.45).Iron ore requires removal of silicate impurities of a finer size by flotation for higher-grade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm.

Vedanta Annual Report 2020-21

We have further strengthened our dust control system by installing new bag houses systems with advanced design at our Blast furnace 2 and Coke screening plant 12. At Iron ore Karnataka, continuing with its best practices, the Company has constructed 38 check dams, 7 settling ponds and 2 harvesting pits having a rainwater harvesting potential

Iron Ore Geoscience Australia

2019114 Iron (Fe) is a metallic element that constitutes 5.6% by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4 ). Hematite is an iron oxide mineral.

Screening 101 911 Metallurgist

2016610 Screening 101. Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower

أدوات للتعدين التانتاليت

آلة سحق فحم حجري

واحد سنگ شکن

رسم وإنشاء الماكينات

المطاحن حجر المطاحن في الصين كسارات المطاحن

طحن سعر OMEC م ومن ناحية تشغيل

سعر طاحونة الحجر في الصين

كسارة السلامة البيئية

تعدين خام التيتانيوم والروتيل في الأرجنتين

فرن دوار للحجر الجيري ذو كفاءة عالية للبيع

الفحم معدات التحميل الألغام

عملية تصنيع الاسمنت جزء لكل تريليون

أي كسارة مطلوبة في أنغولا

ضرب بطة آلة الفداء لعبة مجنون الضفدع عملة تعمل متنزه مجنون الضفدع لعبة آلة محطم

الرصاص الزنك تخطيطات محطة إثراء

تستخدم الفحم الفك سعر كسارة في نيجيريا تستخدم

تصميم مؤسسة مطاحن الكرة

مصنع سحق المحمول في الصين

حجم الشاشة 6120

ليالي الهندسة (المصنعين كسارة الفك في الهند)

المحاجر الصخور للبيع في ولاية أوريغون

هيدروليكية للكسارات

مطحنة مسحوق الجبس مطحنة الريموند

تخطيط مصنع تصنيع مسحوق الكالسيت

ميني بول ميل للبيع في دبي

تهتز آلة غربال للمعدات المعدنية الذهب

Advances in screening technology in the mining sector

1 Introduction2 Growing Demands on Screening Machines3 Screening Machines For Iron Ore and Coal5 Developments in Fine screen Technology6 Prospects

The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. While good quality magnetite is now dry-processed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations. The fineness requirements depend on which me...

Impact of key parameters on the iron ore pellets roller screening

2022610 Thomazini has reported, through discrete element analysis (DEM), the screening efficiency of an iron ore pelletizing plant using a single deck roller screen

Impact of key parameters on the iron ore pellets roller

Abstract. The roller screening process is an important step in the iron ore pellets production. This step is intrinsically linked to the balling production and the induration machine.

Ore Beneficiation an overview ScienceDirect Topics

Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore,

Screening Plant an overview ScienceDirect Topics

The iron ore lump obtained from ROM crushing and screening plants will continue to break down into − 6.3 mm particles during material handling from the product screen to

Optimization of Solids Concentration in Iron Ore Ball Milling

2019618 One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The stone

(PDF) Beneficiation and flowsheet development of

2020121 PDF In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied. The Run of Mine (R.O.M) sample Find, read and cite all the research you

AI Free Full-Text Monitoring of Iron Ore Quality

2022615 Currently, one of the main ways to evaluate the quality of iron ore produced at any stage of the production chain of mining companies is through chemical analysis methodologies of samples, which are

Existing and New Processes for Beneficiation of

202028 Cliff’s Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant, has been applied to produce pellet grade

Iron ore beneficiation: an overview ScienceDirect

202311 Dry processing of iron ore: In dry processing of iron ore, ROM is generally crushed below 40 mm through three-stage crushing and thus segregated by screening into 10–40 and −10 mm fractions. For softer ore, tumbler index is generally low and hence lump ore is crushed below 10 mm to produce 100% fine product. Yield from the plants has

Existing and New Processes for Beneficiation of

202028 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very

Characterization and Beneficiation of Dry Iron Ore Processing Plant

2018918 The generation of iron ore fines in dry processing plant of Khondbond region, India is about 30–40% of the total feed. The iron ore fine assayed 58.73% Fe (T), 5.54% Al 2 O 3, 6.6% SiO 2, and 4.37% LOI. Particle size distribution of fines showed that 50% (by weight) of material are below 1800 μm.

Coal use in iron and steel metallurgy ScienceDirect

201311 Contrary to the almost pure iron of meteoric origin, manufactured iron (pig iron or hot metal) and steel are ferrous alloys of iron with carbon and further impurities (Fig. 12.3).Carbon lowers the melting point of iron from 1538 °C in pure iron to 1147 °C in the eutectic with 4.3% C. Carbon content in steel is up to 2.14 % that corresponds to

Fugitive dust emission control study for a developed smart

202151 The DFDSS was installed in a crushing and screening plant of an iron ore mine in India. Performance study indicted fugitive dust emission concentration values ranged from 354 to 7040 μg m−3, which was reduced to 91–300 μg m −3 after installation of DFDSS. The reduced values were within the permissible limit of 1200 μg m −3 at a

McLanahan breaks the cycle for scrubbing and screening

201966 Original equipment manufacturer (OEM) McLanahan offers a machine that combines both rotary scrubbing and screening functions into a single unit. By combining these two essential functions, the

(PDF) ORE SEPARATION BY SCREENING ResearchGate

201733 Sieving is a process of separation of the ore material into multiple grades by particle size [1]. The screen is a vibrating mining machine, that is driven to motion by a rotating of unbalanced

Crushing Plant Design and Layout Considerations 911

2016224 Ore Characteristics Ore characteristics are a critical element in both crusher selection and plant design. Dry ores require greater provisions for dust suppression and collection, including dust enclosures around screens, sealing on conveyor skirts, and vacuum and wash-down systems. Wet, sticky ores can

(PDF) Iron Ore Sintering: Raw Materials and Granulation

20161028 Abstract and Figures. Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slag-forming elements and coke. The purpose of sintering is to obtain a product

A Mine-to-Crusher Model to Minimize Costs at a Truckless Open-Pit Iron

2022818 Innovation has an important role in improving the productivity, safety and sustainability of mining operations. Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies. The innovative

Developments in iron ore comminution and classification

201511 The largest iron ore company in world, Vale, is developing S11D project, located in the Amazon region of Northern Brazil (Carajás), which is expected to produce 90 million Mtpa of iron ore (Carter, 2011). In designing the innovative, modular ore crushing and screening plant for SD11, Vale was faced with the challenge of coping with the region

Screening, Separation and Vibration Mining Technology

Screening, separation and vibration equipment for the mining industry. Screening, classifying and separation are integral to ore processing, metals and minerals extraction, and controlling the final product quality in any mining and processing operation. Adopting efficient screening and separation solutions can increase yield and productivity

Mobile Screening Station-Multi-Functions, High

2023923 Vibrating Screen: 3YZS2160. Compared with the traditional fixed screening plant, the mobile screening plant has the characteristics of high mobility, strong flexibility, wide adaptation, and

Simulation of Classification and Stratification in Double

202354 The experiment consisted in feeding 10 kg of freshly produced green pellets to the screen during a period of 30 s. The motion of pellets inside the screen was then registered using a high-speed camera (SONY RX-10 IV–Fig. 1), capable of capturing videos at 960 fps. 2.2 Base Case Double-deck Industrial Roller Screen. The base case for the

Minerals Free Full-Text Sensor-Based Ore Sorting

201978 Graphical Abstract. 1. Introduction. Sensor-based ore sorting is gaining increased attention both within and outside the mining industry, as it is leaving the state of pilot plant scale and technology road-mapping, and an increasing amount of equipment is installed in high-capacity production scale environments.

Iron Ore an overview ScienceDirect Topics

Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig. 13.45).Iron ore requires removal of silicate impurities of a finer size by flotation for higher-grade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm.

Vedanta Annual Report 2020-21

We have further strengthened our dust control system by installing new bag houses systems with advanced design at our Blast furnace 2 and Coke screening plant 12. At Iron ore Karnataka, continuing with its best practices, the Company has constructed 38 check dams, 7 settling ponds and 2 harvesting pits having a rainwater harvesting potential

Iron Ore Geoscience Australia

2019114 Iron (Fe) is a metallic element that constitutes 5.6% by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4 ). Hematite is an iron oxide mineral.

Screening 101 911 Metallurgist

2016610 Screening 101. Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower