أرسل لنا رسالة

what kind of stone for jaw crushers

Jaw Crusher an overview ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and

What Are Jaw Crushers and How Do They Work? OreflowWhat Is a Jaw Crusher? Here's How It Works Cutting Jaw Crusher ComponentsParts Mineral ProcessingCrushing Products Size and Shape -What to ExpectWhat Is A Jaw Crusher MEKA:Jaw Crusher SizeRock Crusher Materialsbmchina

What mineral types are good for a jaw crusher? LinkedIn

2023216 mpl mineral Published Feb 16, 2023 + Follow Jaw crushers are most commonly used to crush tougher, harder materials such as basalt, granite and quartz.

What Are the Differences Between The 7 Types of Crushers?All the types of Jaw crusher:Jaw CrushersMining EngineeringJaw Crusher TypesMining Equipment

5 Common Questions about Jaw Crushers Answered

2019530 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as...

:Mining EngineeringJaw Crusher TypesMining Equipment

Jaw Crusher Explained saVRee

Jaw crushers are classified based on the position of the pivoting swing jaw. There are three main jaw crusher types: Blake crusher the swing jaw is fixed at the lower position .

:Mining EngineeringJaw Crusher TypesJaw Crusher In Mining

PE Jaw Crusher LZZG

2023816 Jaw Crusher is a kind of Stone crusher, and jaw crusher is also called Rock crusher. This series of Jaw crushers have many advantages which mainly used in breaking a variety of ore and the

:Jaw CrushersJaw Stone CrusherRock Crushers

What Is A Jaw Crusher MEKA

There are two main groups of jaw crushers, categorized according to their jaw movement mechanism. Single-toggle jaw crushers Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by

:Jaw CrushersMining EngineeringJaw Crusher TypesMining Equipment

Types of Rock Crushers Quarry Crushing

20231030 Sandstone, limestone, gravel, and granite are arguably the most common aggregates used in the construction industry today, but these rocks have very different hardness and abrasiveness characteristics.

:Jaw CrushersMining EngineeringMining EquipmentSecondary Crushing

Jaw Crusher Primary Crusher in Mining

Product Introduction. JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of medium-hard materials to smaller physical size. Jaw rock crushers are capable of

:Jaw CrushersJaw Crusher SizeJaw Crusher In MiningSecondary Crushing

Crushing 101 Different types of crushers for

20201217 For instance jaw or gyratory crushers in primary crushing and cone crushers in secondary crushing. Primary crushing is for the robust. The very first crushers invented were jaw crushers, which are built to

:Jaw CrushersSecondary CrushingGyratory Crushers

Stone Crushers: A Technical Review on Significant Part of

2022513 Stone Crushers: A Technical Review on Significant Part of Construction Industry Kinematic analysis has been done in order to find the effect of any kind of alteration on the performance of the Single toggle jaw crusher 2017 Moses Frank Oduori et al. [12] † Large size rocks as raw materials are fed into primary crushers like jaw crushers

4 Types of Stone Crushers' Maintenance and

2023215 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it

What Kind Of Grease For Jaw Crushers caesarmachinery

What Kind Of Grease For Jaw Crushers. Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. cone crusher grease types Description : Jaw Crusher mpl Jaw Crusher, Impact Crusher, Single

Types Of Crusher- Advantages and Disadvantages

2021119 Old Granite Stone Crusher. There are a few disadvantages of poor-quality granite crushers. It doesn’t have a strong steel frame, so it will just easily collapse or explode. The crane that carries the stone may not be adequately powered and won’t carry the stone sufficiently far away from workers.

Jaw Crusher an overview ScienceDirect Topics

Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported underground for installation. Modern jaw crushers may have a main frame of welded mild steel plate.

How To Crush Stone? The Ultimate Guide Komplet America

20231025 Crushing stones into smaller sizes might seem like a task requiring much effort, but the whole process is easy if you use the right equipment in a stone crush plant. For example, soft rocks such as sandstone can easily break down using an excavator with an attached hydraulic breaker. In contrast, harder rocks such as granite, trap rock, and

Crushers 911 Metallurgist

20161023 Crushers. It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding, but in the main, crushing may be said to cover the reduction of stones or ores to a size of ½ inch, and in some cases slightly less.

Types of Crushing Equipment Jaw, ConeImpact

Choosing The Right Crusher A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks of a maximum size. It

PE Series Jaw Crusher For Primary Crushing mpl

Jaw crusher is the traditional crushing equipment with many models and large output. PE jaw crusher is mainly used for primary crushing of various ores and undisturbed materials, also used for both coarse and fine crushing. There are many models of PE jaw crushers, among which the most popular models are PE-750×1060, PE-600×900, PE-150×250, etc.

Crushing Astec

20231030 Astec designs and manufactures a wide range of quality crushing equipment that is technology-driven and durably-designed for modern crushing operations. Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers,

Stone Crusher For Sale Produce High-quality Aggregate

The jaw stone crusher machine is suitable for primary crushing equipment. The jaw crusher has a strong crushing force and a high crushing degree. It is suitable for the crushing and processing of hard and medium-hard ores. Different types of jaw stone crushers can achieve different degrees of crushing, that is coarse crushing, medium crushing

Choosing the right crusher for rock, stone, concrete and

Choosing the right crusher. Aggregate producers and recyclers use rock crushers to reduce the size of rock, stone, concrete and asphalt rubble to produce construction materials like base gravel and new concrete and asphalt mixes. Several types of crushers are available in the marketplace, but jaw, cone, and impactors are the most commonly used

Aimix Stone Crusher Plant In The Philippines for

Technical advantages of APJ Series Stone Jaw Crushers. High-efficiency cavity design, high crushing efficiency. It has advanced movable jaw assembly of the crusher.The crushing cavity structure and movable jaw

What kind of crushing equipment is needed to produce

2023216 Some common types of crushing equipment used in cement production include: Jaw Crushers: These are typically used for primary crushing of large chunks of raw materials such as limestone, clay, and

Construction Working and Maintenance of Crushers for

20181226 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 References 53 . 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance.net

What Are Jaw Crushers and How Do They Work? Oreflow

March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone. From there, jaw crushers have seen plenty of action in the pit and quarry

8 Tips for Crusher Safety Stewart-Amos Equipment Company

20221027 6. Perform Proper Shutdown Process. Ending the operation of a crusher is an essential part of crusher safety. There are a few steps to follow when shutting down a crusher that every trained worker should follow: Shut down the apron feeder. Ensure equipment is free of material. Shut down the primary crusher.

Jaw Crushers Mellott

Expert Jaw Crusher Rental Services From Mellott. If you are in need of some heavy-duty rock crushing capabilities, our team can help you learn about the best jaw crusher options for your next project. Save time and money by renting from our professionally maintained line of equipment. Reach out to our team today at (855) 554-1606 to learn more.

News What kind of stone crusher machines are the best

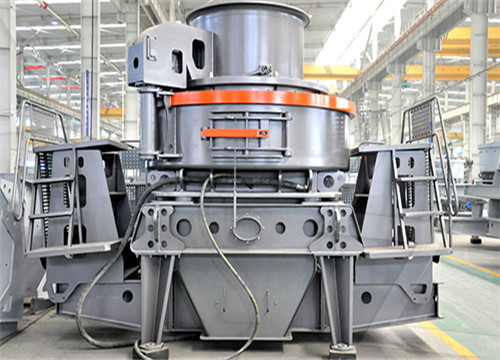

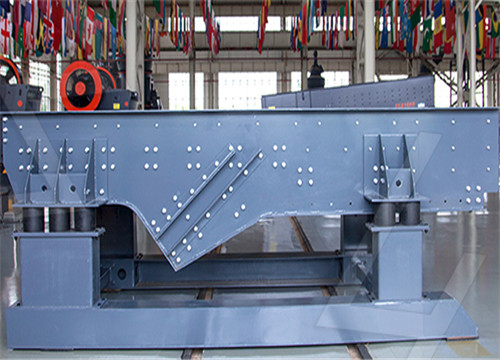

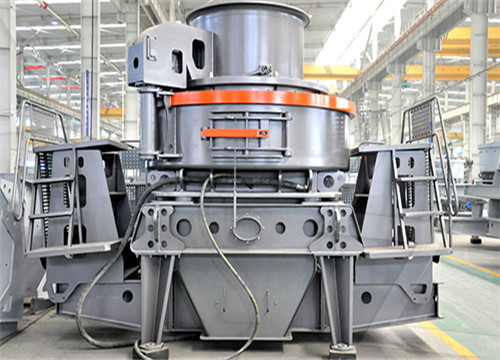

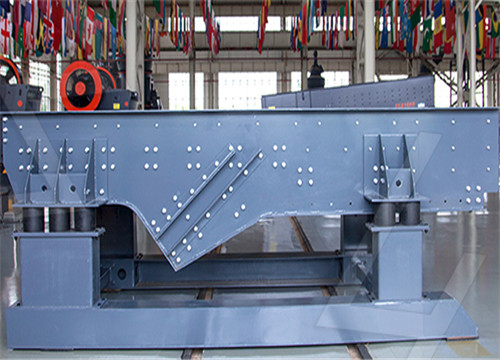

202381 Mining crushers are dedicated to crushing ore materials and are used in the construction industry. Commonly used are jaw crushers, impact crushers, cone crushers, hammer crushers, impact crushers, and mobile crushers. Wait, we choose three more advanced equipment, users buy more equipment to introduce in detail. 1. Jaw crusher

Understanding the Different Types of Crushers Agg-Net

2018910 Jaw crushers. A jaw crusher is a compression type of crusher. Feed material is reduced by squeezing it between a moving piece of steel and a stationary piece of steel, with the discharge size controlled by the gap setting, ie the space between those two pieces of steel. This promotes stone-on-stone crushing, which breaks up flaky or

What mineral types are good for a jaw crusher? LinkedIn

2023216 mpl mineral Published Feb 16, 2023 + Follow Jaw crushers are most commonly used to crush tougher, harder materials such as basalt, granite and quartz.

5 Common Questions about Jaw Crushers Answered

2019530 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as...

Jaw Crusher Explained saVRee

Jaw crushers are classified based on the position of the pivoting swing jaw. There are three main jaw crusher types: Blake crusher the swing jaw is fixed at the lower position .

PE Jaw Crusher LZZG

2023816 Jaw Crusher is a kind of Stone crusher, and jaw crusher is also called Rock crusher. This series of Jaw crushers have many advantages which mainly used in breaking a variety of ore and the

What Is A Jaw Crusher MEKA

There are two main groups of jaw crushers, categorized according to their jaw movement mechanism. Single-toggle jaw crushers Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by

Types of Rock Crushers Quarry Crushing

20231030 Sandstone, limestone, gravel, and granite are arguably the most common aggregates used in the construction industry today, but these rocks have very different hardness and abrasiveness characteristics.

Jaw Crusher Primary Crusher in Mining

Product Introduction. JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of medium-hard materials to smaller physical size. Jaw rock crushers are capable of

Crushing 101 Different types of crushers for

20201217 For instance jaw or gyratory crushers in primary crushing and cone crushers in secondary crushing. Primary crushing is for the robust. The very first crushers invented were jaw crushers, which are built to

Stone Crushers: A Technical Review on Significant Part of

2022513 Stone Crushers: A Technical Review on Significant Part of Construction Industry Kinematic analysis has been done in order to find the effect of any kind of alteration on the performance of the Single toggle jaw crusher 2017 Moses Frank Oduori et al. [12] † Large size rocks as raw materials are fed into primary crushers like jaw crushers

4 Types of Stone Crushers' Maintenance and

2023215 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it

What Kind Of Grease For Jaw Crushers caesarmachinery

What Kind Of Grease For Jaw Crushers. Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. cone crusher grease types Description : Jaw Crusher mpl Jaw Crusher, Impact Crusher, Single

Types Of Crusher- Advantages and Disadvantages

2021119 Old Granite Stone Crusher. There are a few disadvantages of poor-quality granite crushers. It doesn’t have a strong steel frame, so it will just easily collapse or explode. The crane that carries the stone may not be adequately powered and won’t carry the stone sufficiently far away from workers.

Jaw Crusher an overview ScienceDirect Topics

Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported underground for installation. Modern jaw crushers may have a main frame of welded mild steel plate.

How To Crush Stone? The Ultimate Guide Komplet America

20231025 Crushing stones into smaller sizes might seem like a task requiring much effort, but the whole process is easy if you use the right equipment in a stone crush plant. For example, soft rocks such as sandstone can easily break down using an excavator with an attached hydraulic breaker. In contrast, harder rocks such as granite, trap rock, and

Crushers 911 Metallurgist

20161023 Crushers. It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding, but in the main, crushing may be said to cover the reduction of stones or ores to a size of ½ inch, and in some cases slightly less.

Types of Crushing Equipment Jaw, ConeImpact

Choosing The Right Crusher A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks of a maximum size. It

PE Series Jaw Crusher For Primary Crushing mpl

Jaw crusher is the traditional crushing equipment with many models and large output. PE jaw crusher is mainly used for primary crushing of various ores and undisturbed materials, also used for both coarse and fine crushing. There are many models of PE jaw crushers, among which the most popular models are PE-750×1060, PE-600×900, PE-150×250, etc.

Crushing Astec

20231030 Astec designs and manufactures a wide range of quality crushing equipment that is technology-driven and durably-designed for modern crushing operations. Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers,

Stone Crusher For Sale Produce High-quality Aggregate

The jaw stone crusher machine is suitable for primary crushing equipment. The jaw crusher has a strong crushing force and a high crushing degree. It is suitable for the crushing and processing of hard and medium-hard ores. Different types of jaw stone crushers can achieve different degrees of crushing, that is coarse crushing, medium crushing

Choosing the right crusher for rock, stone, concrete and

Choosing the right crusher. Aggregate producers and recyclers use rock crushers to reduce the size of rock, stone, concrete and asphalt rubble to produce construction materials like base gravel and new concrete and asphalt mixes. Several types of crushers are available in the marketplace, but jaw, cone, and impactors are the most commonly used

Aimix Stone Crusher Plant In The Philippines for

Technical advantages of APJ Series Stone Jaw Crushers. High-efficiency cavity design, high crushing efficiency. It has advanced movable jaw assembly of the crusher.The crushing cavity structure and movable jaw

What kind of crushing equipment is needed to produce

2023216 Some common types of crushing equipment used in cement production include: Jaw Crushers: These are typically used for primary crushing of large chunks of raw materials such as limestone, clay, and

Construction Working and Maintenance of Crushers for

20181226 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 References 53 . 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance.net

What Are Jaw Crushers and How Do They Work? Oreflow

March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone. From there, jaw crushers have seen plenty of action in the pit and quarry

8 Tips for Crusher Safety Stewart-Amos Equipment Company

20221027 6. Perform Proper Shutdown Process. Ending the operation of a crusher is an essential part of crusher safety. There are a few steps to follow when shutting down a crusher that every trained worker should follow: Shut down the apron feeder. Ensure equipment is free of material. Shut down the primary crusher.

Jaw Crushers Mellott

Expert Jaw Crusher Rental Services From Mellott. If you are in need of some heavy-duty rock crushing capabilities, our team can help you learn about the best jaw crusher options for your next project. Save time and money by renting from our professionally maintained line of equipment. Reach out to our team today at (855) 554-1606 to learn more.

News What kind of stone crusher machines are the best

202381 Mining crushers are dedicated to crushing ore materials and are used in the construction industry. Commonly used are jaw crushers, impact crushers, cone crushers, hammer crushers, impact crushers, and mobile crushers. Wait, we choose three more advanced equipment, users buy more equipment to introduce in detail. 1. Jaw crusher

Understanding the Different Types of Crushers Agg-Net

2018910 Jaw crushers. A jaw crusher is a compression type of crusher. Feed material is reduced by squeezing it between a moving piece of steel and a stationary piece of steel, with the discharge size controlled by the gap setting, ie the space between those two pieces of steel. This promotes stone-on-stone crushing, which breaks up flaky or