أرسل لنا رسالة

aggregate crushing plant process diagram pdf

11.19.1 Sand And Gravel Processing US EPA

2015910 The processing of sand and gravel for a specific market involves the use of different combinations of washers, screens, and classifiers to segregate particle sizes;

Optimization Framework for Crushing Plants Chalmers

A typical crushing plant consists of size reduction machines (e.g., crushers) with intermediate separation machines (e.g., screens), transportation equipment (e.g.,

Aggregate Production Optimization in a Stone-Crushing Plant

202028 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal

(PDF) Optimization Capabilities for Crushing Plants

2022426 The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the

Crushing and Screening Handbook AusIMM

2021624 stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both

(PDF) Influence of Natural Aggregate Crushing

2021727 This analysis showed how important the process of grinding aggregates is and, thus, the appropriate selection of fractions for the grit crushing process for the aggregate strength on...

(PDF) AGGREGATE CRUSHING PLANT Birhanu

Crushing plant of TDT 3.3. Storage The end materials are then taken by loaders and stocked on appropriate places until selling. Normally fine aggregates are moved directly.

Concrete aggregates properties crushed by jaw and impact secondary crushing

201911 Given that crushing is fundamental for phase liberation, this stone compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates

MODELLING, SIMULATION AND OPTIMISATION OF A

2017823 crushing circuit of the Mowana production chain. The major hypotheses of this research are that performance in a crushing plant is adversely influenced by

(PDF) Factors affecting the performance of

201411 PDF Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider sustainable development. Find, read and cite all the research...

Crushing and Screening Handbook AusIMM

2021624 stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of proc-esses, such as crushing and screening

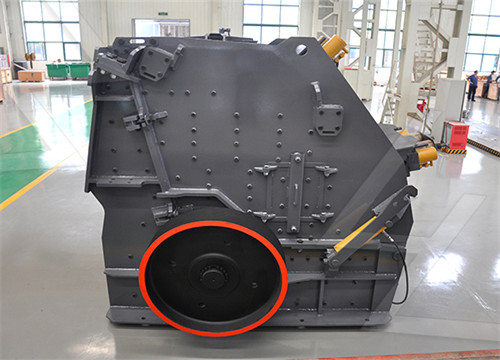

Stone Crushers: A Technical Review on Significant Part of

2022514 2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing.

11.12 Concrete Batching US EPA

2018924 Figure 11.12-1 is a generalized process diagram for concrete batching. The raw materials can be delivered to a plant by rail, truck or barge. The cement is transferred to elevated storage silos pneumatically or by bucket elevator. The sand and coarse aggregate are transferred to elevated bins by front end loader, clam shell crane,

11.12 Concrete Batching US EPA

2015910 11.12.1 Process Description1-4 Concrete is composed essentially of water, cement, sand (fine aggregate), and coarse aggregate. Figure 11.12-1 is a generalized process diagram for concrete batching. The raw materials can be delivered to a plant by rail, truck, or barge. l2Assumes 1,011 m (1/4 acre) of sand and aggregate storage at plant

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Concrete aggregates properties crushed by jaw and impact secondary crushing

201911 The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms

Process of Stone Crushing PDF Economic Sectors Nature

2022524 4.1 PROJECT DESCRIPTION. As indicated at Section 1 Project Particulars, the project consists of the setting-up. and operation of a stone-crushing plant and of four other inter-linked plants (namely: block making plant, ready-mix concrete plant, pre-mixed asphalt plant and precast. production) over a portion of land of 70,668m2at

(PDF) Optimization Capabilities for Crushing Plants

2022426 The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for identification and exploration of operational

Mineral Processing Plant Design University of

2018119 Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital There are three main steps in designing a good crushing plant: process design, equipment selection, and layout.

11.19.2 Crushed Stone Processing US EPA

2015910 Quarried stone normally is delivered to the processing plant by truck and is dumped into a hoppered feeder, usually a vibrating grizzly type, or onto screens, as illustrated in Figure 11.19.2-1. The feeder or screens separate large boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher.

Aggregate Production Optimization in a Stone-Crushing Plant

202028 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

(PDF) AGGREGATE CRUSHING PLANT Birhanu

The ceramic waste crushed tiles were partially replaced in place of coarse aggregates by 10%, 20%, 30%, 40% and 50%. Rebutted tyre waste and ceramic tile powder were replaced in place of fine aggregate by 10%

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Crushing plant with a single-toggle jaw crusher in materials and jaw settings are shown in the diagram. The grain size distribution curves of the product are only guide Serrated jaw plates enhance the crushing process. When the 200 250 300 350 400 1,600 1,400 1,200 1,000 800 600 400 200

Crushing PPT SlideShare

20191112 Crushing Download as a PDF or view online for free. 9.Types of jaw crusher Jaw crushers are classified by the method of pivoting the swing jaw. In the blake jaw crusher the swing jaw is fixed at the top. It has fixed receiving area but variable discharge opening. In dodge jaw crusher the swing jaw is pivoted at the bottom. It has variable feed

Environmental Impact and Sustainability of Aggregate Production in

2020311 The production of aggregate for the infrastructural development of the country has been increasing for the last three decades due to the high urbanization rates in the main cities of the country and the ever-growing demand for basic infrastructural facilities. The environmental impact of both fine and coarse aggregate production is now hard to

S19 MaintenanceInspection Of PlantEquipment Agg

20231030 427.61 KB. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. The Maintenance and Inspection Procedure outlines what is required in a scheme for maintenance and inspection including: Boundaries. Pedestrian and traffic routes.

Enhanced Plant Design for Aggregate Processing Agg-Net

20121015 Armed with such data, it is then feasible to proceed with the process of flow concept design, and the following are general points to be borne in mind for building an effective crushing and screening plant. Evaluation and calculation. The intention is to evaluate the content of the plant from in-feed to the plant through the various process

Overview of the Sand and Aggregate Industry-edited

Figure 1: Basic flow diagram of the sand and aggregate industry 4. OWNERSHIP, BEE AND SMALL SCALE MINING manufacturing plants Crushing AGGREGATE Screening Blending (optional) Washing (optional during plant process) OVERVIEW OF THE SAND AND AGGREGATE INDUSTRY, 2008

Aggregate Crushing Value Test Procedure, Result

1 The aggregate crushing value formula is given below, Aggregate crushing value = (W3 / W) or W3 / (W2 W1) W1 = Empty weight of cylindrical Measure. W2 = Weight of Aggregate with Cylindrical Measure. W = W2 –W1 = Weight of Aggregate Sample. W3 = Weight of crushed aggregate sample passed through 2.36 mm IS Sieve.