أرسل لنا رسالة

create problem in hammer crusher machine

9 Hammer Crusher Common Faults and Solutions Fote

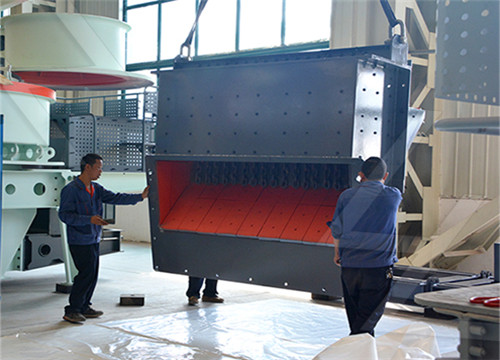

202354 b. The lining fastener is loose and the hammer strikes the lining; c. Hammer or other parts are broken. Solutions: a. Stop and clean up the crushing cavity; b. Check the fastening of the lining plate and the gap between the hammer and the screen; c. Replace

7 Hammer Crusher Common Problems And

Bearing heat Reason: improper bearing design selection. The processing accuracy of hammer crusher parts can not meet the requirements. Poor

Hammer Crusher: The 10 Most Important Points MIXING

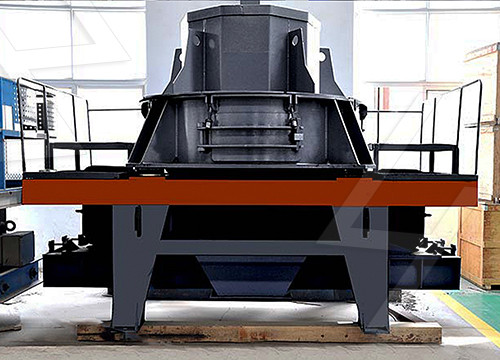

2022815 The hammer crusher mainly relies on the rotor to drive the hammer, and the impact force of the hammer crushes the material. It is mainly composed of a rotor, a

Six Major Faults and Solutions of Hammer Crusher Luoyang

2021820 Here, we introduce six major faults and solutions of the hammer crusher. Working principle of hammer crusher: The motor of hammer crusher drives the rotor to

Study of the Energy-Power Parameters of the Crushing Process in Hammer

202336 Research goals: development of analytical method of determination of energy-power parameters of the drive of the hammer crusher with the grate;

(PDF) Design and Evaluation of Crushing Hammer

201911 PDF A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided Find, read and cite all the research you

Drive power calculation of a crushing machine working

2 Problem statement The power of the electric motor is determined taking into account the power expended to overcome all resistance forces during the operation of the crusher: N

Minerals Free Full-Text Industry Scale Optimization: Hammer Crusher

20211231 The working part of the hammer crusher—the rotor—is most often made of round discs. The discs are mounted on the axis with spaces preserved between them.

Study of the Energy-Power Parameters of the Crushing

202336 Using the method of equivalent power required for the electric motor drive of the crushing machine at the steady mode of operation and basic laws of general

7 common faults and solutions for Hammer

2019108 Solution: remove the hammer head and select the hammer head according to the weight, so that the total weight of the hammer on each hammer shaft is equal to the total weight of the hammer...

Finite Element and Multibody Dynamics Analysis

20221229 Fladvad and Onnela [] studied the influence of jaw crusher parameters on the quality of primary crushed aggregates.In the hammer crusher (Figure 2), hammerheads of high wear resistance and

Types of Crushers: What You Need to Know Machinery

Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Improved Hammers for Crushers in Feed Production

20221215 The design of hammers for crushers is considered on the basis of a mathematical model of cracking in the production of bone meal. The proposed hammer design permits intensification of crushing. An important agricultural feedstuff is bone meal, produced by grinding animal wastes. Hammer-based crushers prove effective in

Experimental Investigation of a New Modular Crusher Machine

2022930 The crushing system is crucial in the virgin olive oil (VOO) mechanical extraction process. The use of different crusher machines can highly influence the quality of the final product, mainly due to the phenolic and volatile content responsible for VOO sensory and health properties. An experimental investigation was conducted to evaluate

Study of the Energy-Power Parameters of the Crushing

202336 hammer crusher with a grate is proposed. Using the method of equivalent power required for the electric motor drive of the crushing machine at the steady mode of operation and basic laws of general mechanics, we explain the following: the dependences of the resistance torque on the crushing force of the free impact ham-

Large Capacity Hammer Crusher DASWELL

202398 HC series crusher machine is a small hammer crusher which can be installed with 16-24 hammer heads. This hammer mill crusher is suitable for crushing materials with size less than 350mm into finished materials with size less than 15mm. The impact hammer crusher should be carefully checked before operation to avoid low

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

What Is A Jaw Crusher MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.)

Hammer Crushers MEKA

HAMMER CRUSHER / TECHNICAL SPECIFICATIONS. metric; imperial; MHC 1014: MHC 1214: Rotor Diameter (mm) Rotor Diameter (inch) 1000 39: 1200 47: Rotor Width (mm) Rotor Width (inch) 1400 55: WE CREATE RIGHT SOLUTIONS TO AGGREGATE PRODUCTION, READY-MIX CONCRETE AND MINING INDUSTRIES.

(PDF) DEVELOPMENT OF A HORIZONTAL SHAFT

20191223 A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need. The power required to deliver the through put efficiency of the

Hammer Mill CrusherGrinder 911 Metallurgist

2016225 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

Hammer Crusher Machine Hammer Crusher

Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts. The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head. The

(PDF) Design and Evaluation of Crushing Hammer mill

201911 A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software. Suitability of

Advanced comminution modelling: Part 1 Crushers

2020121 A cone crusher is a machine that breaks rocks by squeezing them between an eccentrically gyrating cone (also called a mantle) and a concave [11]. Particles enter the cone crusher from the top, travel down as a packed bed until they are near the working surfaces where they become trapped between the mantle and the concave and are in

Hammer Crusher Working for Cement Plant AGICO CEMENT

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a

3 Reasons Why Your Hammer Crusher's Discharge Size Is

2021927 Here, you might need to replace a damaged screen or plate. Once you have a new one in place, your crusher should work to the right sizing again. 3. Your Hammer Is Damaged. Your crusher's hammer has to do a hard and strenuous job. It bashes away at hard materials all the time. Sometimes, hammers can stop working effectively.

BTMA-The working principle for a hammer crusher BTMA

20211222 To crush materials, the hammer crusher relies mainly on impact energy. The motor drives the rotor at high speed to cause the hammer crusher to work. This allows the material to enter the crusher cavity in an even manner. The material is broken by the high-speed rotating Hammer. The material’s gravity causes it to move at the same time.

Crusher an overview ScienceDirect Topics

A design for a hammer crusher (Figure 2.6) Crusher machines are equipped with a pair of crusher jaws namely; fixed jaws and swing jaws. Both jaws are fixed in a vertical position at the front end of a hollow rectangular frame of crushing machine as shown in Fig. 10.1. The swing jaw is moved against the fixed jaws through knuckle action by

Experimental Studies of the Process of Crushing Coal

processed raw materials. To solve this problem on the developed physical model of hammer crusher studies have been conducted to determine the power spent on crushing the coal charge and overcoming the resistance rotation of its rotor from a dusty coal atmosphere, and a check was also performed the adequacy of existing